The realm of optoelectronic components has revolutionized how we approach electronic design and implementation across numerous industries. These sophisticated devices, which convert light signals to electrical signals and vice versa, form the backbone of many modern technological advances. From telecommunications to consumer electronics, the proper selection of optoelectronic components can mean the difference between a project's success or failure.

Engineers and designers face increasingly complex decisions when choosing these critical components. The market offers an extensive range of options, each with specific characteristics and applications. Understanding how to navigate these choices requires both technical knowledge and practical insight into project requirements.

When selecting optoelectronic components, performance specifications serve as the primary consideration. Key parameters include spectral response, sensitivity, response time, and operating temperature range. These specifications must align precisely with your project's requirements to ensure optimal functionality.

The wavelength range of operation is particularly crucial, as it determines the component's compatibility with your system's light sources and detectors. Additionally, consider the quantum efficiency and responsivity ratings, which indicate how effectively the component converts light to electrical signals or vice versa.

Environmental factors significantly impact the performance and longevity of optoelectronic components. Temperature variations, humidity levels, and exposure to electromagnetic interference can all affect component behavior. Selecting components with appropriate IP ratings and operating temperature ranges ensures reliable operation in your intended environment.

Consider the mean time between failures (MTBF) and component lifetime ratings. These metrics help predict long-term reliability and maintenance requirements. For industrial applications, components may need additional protection against vibration, shock, and harsh environmental conditions.

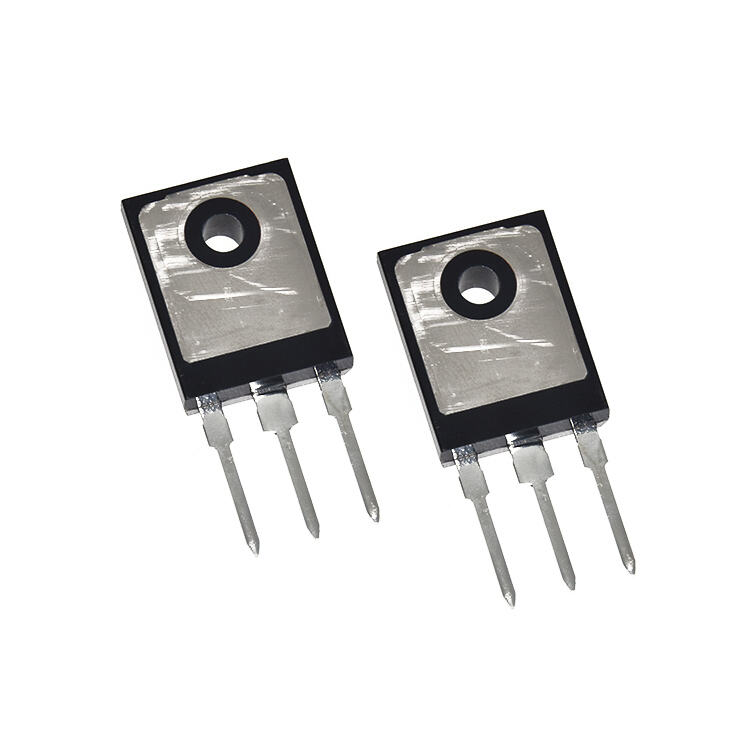

The physical characteristics of optoelectronic components play a crucial role in their selection. Form factor, pin configuration, and mounting options must align with your PCB design and space constraints. Consider factors such as component height, footprint, and thermal management requirements during the selection process.

Connection interfaces and packaging types also warrant careful attention. Surface-mount devices (SMD) offer advantages in automated assembly, while through-hole components might be preferred for prototyping or specific application requirements. The availability of evaluation boards and development kits can significantly facilitate the integration process.

Electrical compatibility ensures seamless integration with other system components. Key considerations include power requirements, voltage levels, and current consumption. The selected optoelectronic components must work harmoniously with your power supply design and control circuitry.

Signal conditioning requirements and noise immunity characteristics deserve special attention. Some components may require additional circuitry for proper operation, such as amplifiers, filters, or level shifters. Understanding these requirements early in the selection process helps prevent integration issues later.

While component price is important, the total cost of ownership extends beyond the initial purchase price. Consider factors such as installation costs, power consumption, maintenance requirements, and potential replacement needs. Some premium optoelectronic components may offer better value through improved efficiency or longer service life.

Development costs, including testing and qualification processes, should also factor into your decision. The availability of technical support and documentation from manufacturers can significantly impact development time and associated costs.

The reliability of your component supply chain affects both production schedules and long-term maintenance capabilities. Evaluate manufacturers' production capacity, lead times, and minimum order quantities. Consider multiple sourcing options to mitigate supply chain risks.

Component lifecycle management is crucial for long-term projects. Select components with established production histories and clear roadmaps for future availability. Some manufacturers offer lifecycle guarantees or last-time-buy options for critical components.

The optoelectronic component market continues to evolve rapidly. Stay informed about emerging technologies and industry trends that might affect your component selection. Consider whether newer technologies might offer significant advantages in terms of performance, efficiency, or cost.

Evaluate the potential for future upgrades or modifications to your design. Selecting components with some performance headroom or additional features might provide flexibility for future enhancements without requiring complete redesign.

Regulatory requirements and industry standards continue to evolve, particularly regarding energy efficiency and environmental impact. Choose components that comply with current regulations and consider potential future requirements. This foresight can prevent costly redesigns or compliance issues later.

International standards and certification requirements may affect your component selection, especially for products intended for global markets. Understanding these requirements early in the selection process ensures smooth certification and market entry.

Temperature variations can significantly impact the performance characteristics of optoelectronic components, including wavelength shift, efficiency changes, and lifetime reduction. Most components specify operating temperature ranges and temperature coefficients in their datasheets. Proper thermal management and component selection based on environmental conditions are essential for reliable operation.

Analog optoelectronic components provide continuous output signals proportional to input light intensity, while digital components operate in discrete states. Digital components often offer better noise immunity and easier integration with microprocessors, but analog components may provide more precise measurements and faster response times in certain applications.

To ensure long-term availability, work with established manufacturers, review product lifecycle documentation, and consider multiple sourcing options. Many manufacturers offer product longevity programs or can provide guidance on migration paths to newer components. Maintaining relationships with reliable distributors and staying informed about market conditions also helps manage component availability.