inverter pcb board price

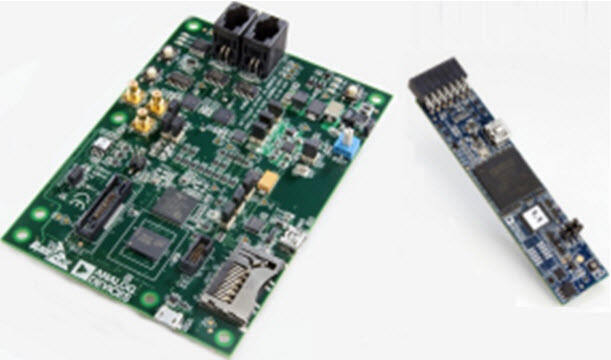

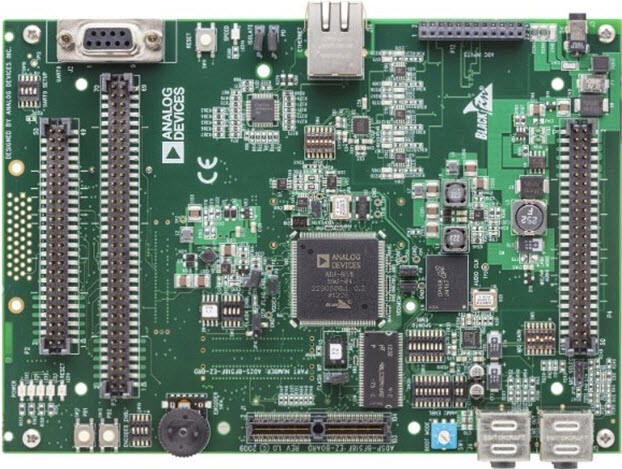

The inverter PCB board price represents a critical consideration in the power electronics industry, reflecting the sophisticated technology and quality components required for reliable power conversion systems. These specialized circuit boards serve as the backbone of modern inverter systems, converting DC power to AC power efficiently and reliably. The pricing structure typically varies based on several factors, including component quality, manufacturing complexity, and production volume. Standard inverter PCB boards incorporate advanced circuitry designs, featuring multiple layers of copper traces, high-grade insulation materials, and precision-engineered components. The cost considerations encompass not only the raw materials but also the specialized manufacturing processes, quality control measures, and testing procedures necessary to ensure optimal performance. Modern inverter PCB boards often include features such as thermal management systems, protection circuits, and intelligent control interfaces, all of which influence the final price point. The market offers various price ranges to accommodate different applications, from residential solar systems to industrial power conversion equipment, with costs typically ranging from economical options for basic functionality to premium solutions for high-performance requirements.