pcba manufacturer

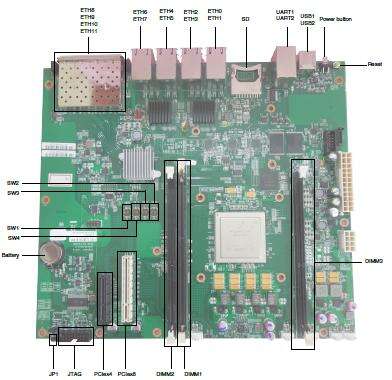

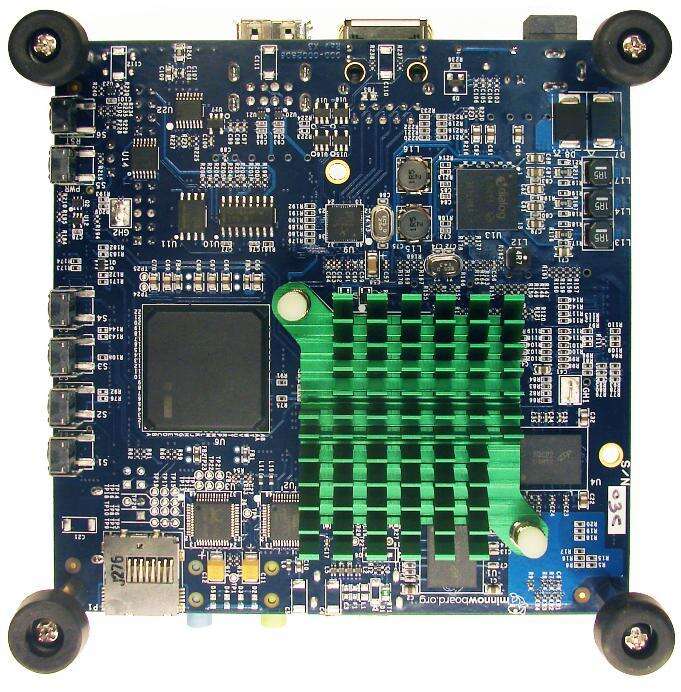

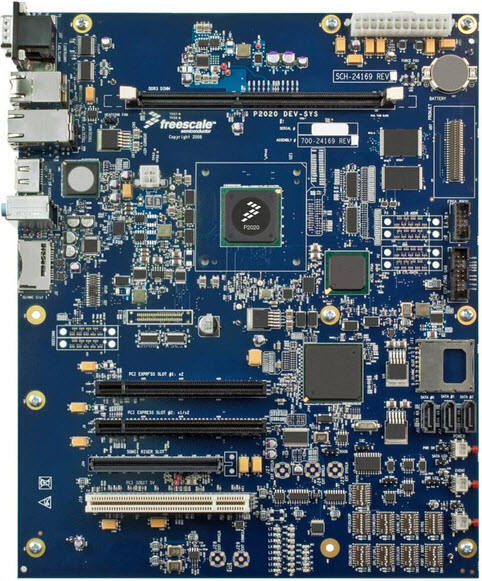

A PCBA manufacturer stands as a crucial player in the electronics manufacturing industry, specializing in the complete assembly of printed circuit boards (PCBs). These facilities combine cutting-edge technology with precision engineering to transform bare circuit boards into fully functional electronic assemblies. Modern PCBA manufacturers employ state-of-the-art surface mount technology (SMT) lines, automated optical inspection systems, and advanced testing equipment to ensure the highest quality standards. They handle everything from component procurement and placement to soldering, testing, and quality assurance. These manufacturers support diverse industries, including automotive electronics, telecommunications, medical devices, and consumer electronics. Their capabilities typically include both prototype and high-volume production, with flexibility to accommodate various board sizes and complexity levels. They maintain strict adherence to international manufacturing standards such as ISO 9001, IPC standards, and RoHS compliance. Advanced PCBA manufacturers also offer value-added services like design for manufacturability (DFM) review, component engineering, and supply chain management, ensuring optimal production efficiency and cost-effectiveness for their clients.