pCBA-Dienstleistung

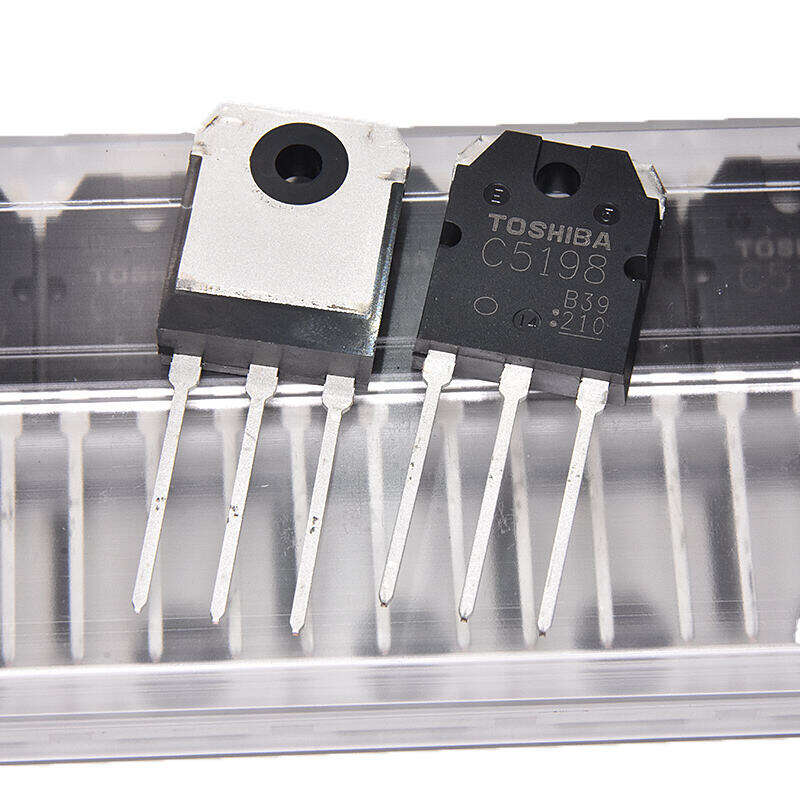

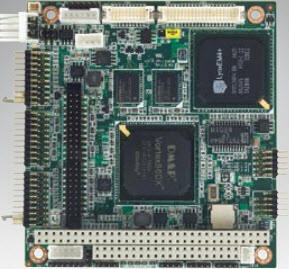

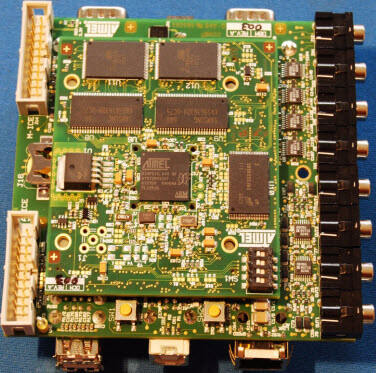

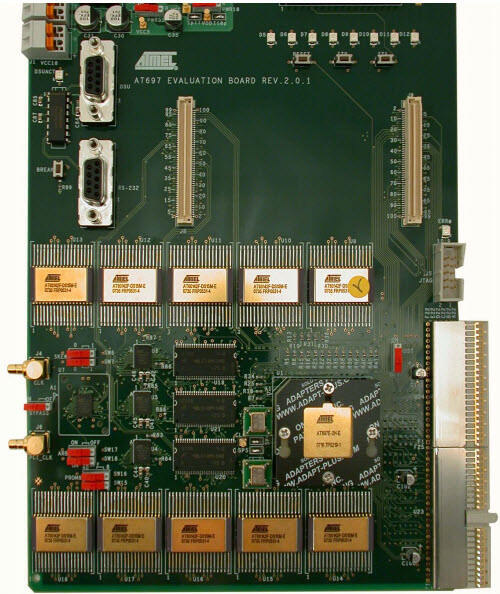

Der PCBA (Printed Circuit Board Assembly)-Service stellt eine umfassende Lösung in der Elektronikfertigung dar und umfasst den kompletten Prozess der Bestückung von Leiterplatten mit elektronischen Bauteilen. Dieser anspruchsvolle Service kombiniert modernste Technologie mit präziser Ingenieurskunst, um voll funktionsfähige elektronische Baugruppen herzustellen. Der Prozess beginnt mit der Beschaffung unbelegter Leiterplatten und erstreckt sich über die Bauteilbestückung, das Löten, Testverfahren und die Qualitätssicherung. Moderne PCBA-Services nutzen fortschrittliche SMD-Technologien (Surface Mount Technology) sowie Durchsteckmontageverfahren, unterstützt durch automatisierte optische Inspektionssysteme (AOI) und Röntgeninspektionsverfahren, um optimale Qualität sicherzustellen. Der Service deckt verschiedene Produktionsvolumina ab, von Prototypenfertigungen bis zur Serienproduktion, und gewährleistet dabei konstante Qualitätsstandards. PCBA-Anbieter bieten in der Regel eine Design-for-Manufacturability-(DFM)-Analyse, Beschaffung von Bauteilen sowie Supply-Chain-Management an. Diese Dienstleistungen sind in zahlreichen Branchen unverzichtbar, darunter Unterhaltungselektronik, Automobilindustrie, Medizintechnik und industrielle Automatisierung. Die Integration von Industrie-4.0-Prinzipien ermöglicht eine Echtzeitüberwachung der Produktion und Qualitätssicherung und sorgt so für hohe Ausschussminimierung und Zuverlässigkeit des Endprodukts.