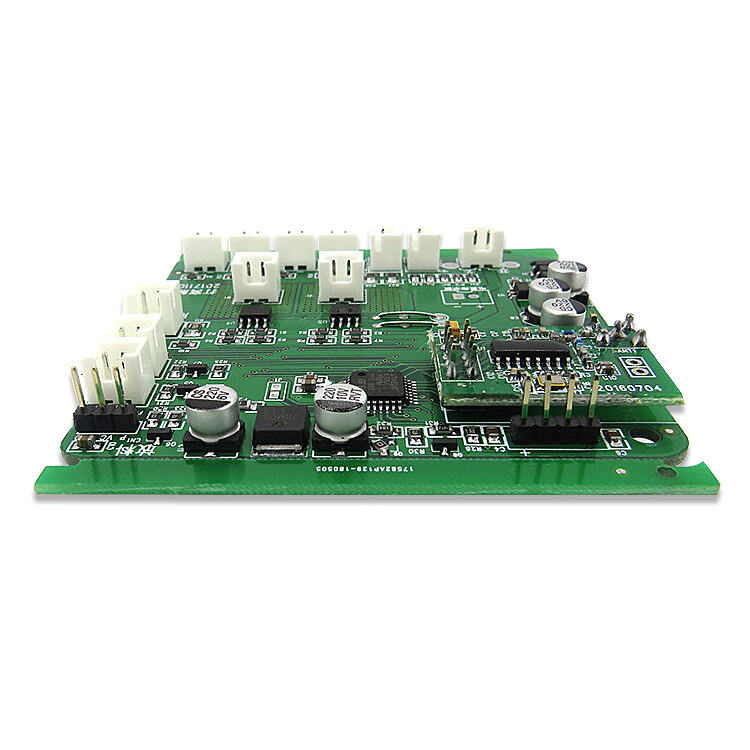

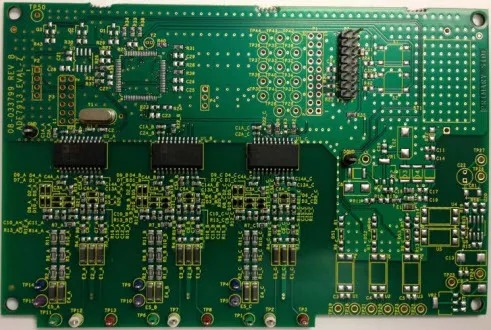

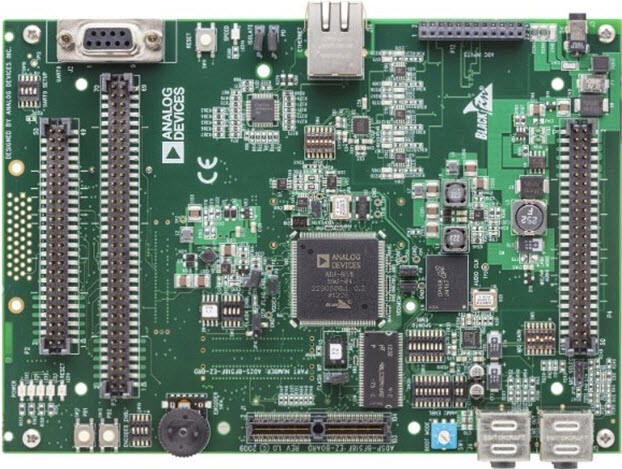

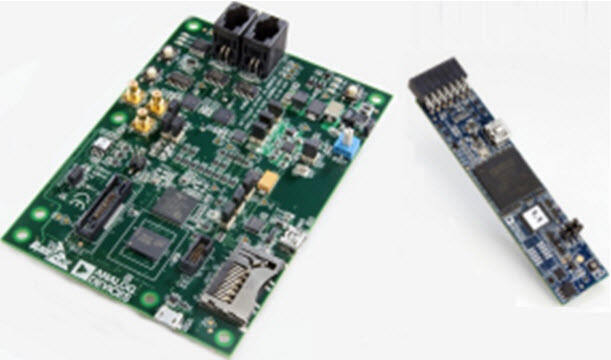

saldatura della scheda pcb

Una scheda PCB per saldatura è uno strumento specializzato progettato per l'assemblaggio preciso di componenti elettronici e la produzione di circuiti stampati. Questa attrezzatura essenziale combina sistemi avanzati di controllo della temperatura con un design ergonomico per facilitare operazioni di saldatura accurate ed efficienti. La scheda dispone di diverse zone operative che accolgono componenti di dimensioni differenti e diverse esigenze di saldatura, garantendo versatilità in vari progetti elettronici. La sua superficie è generalmente realizzata con materiali resistenti ad alte temperature, in grado di sopportare esposizioni continue al calore della saldatura mantenendo l'integrità strutturale. Le moderne schede PCB per saldatura incorporano caratteristiche innovative come protezione anti-statica, regolazione del calore e sistemi di raffreddamento integrati per prevenire danni ai componenti. Queste schede sono fondamentali sia nella produzione professionale di elettronica sia nei progetti fai-da-te, supportando processi di saldatura attraverso fori (through-hole) e tecnologia a montaggio superficiale (SMT). Il design include spesso aree dedicate all'organizzazione dei componenti, all'applicazione del flussante e alle operazioni di pulizia, ottimizzando l'intero flusso di lavoro di saldatura. I modelli più avanzati possono includere funzionalità integrate di test per verificare immediatamente la qualità delle connessioni e il funzionamento del circuito.