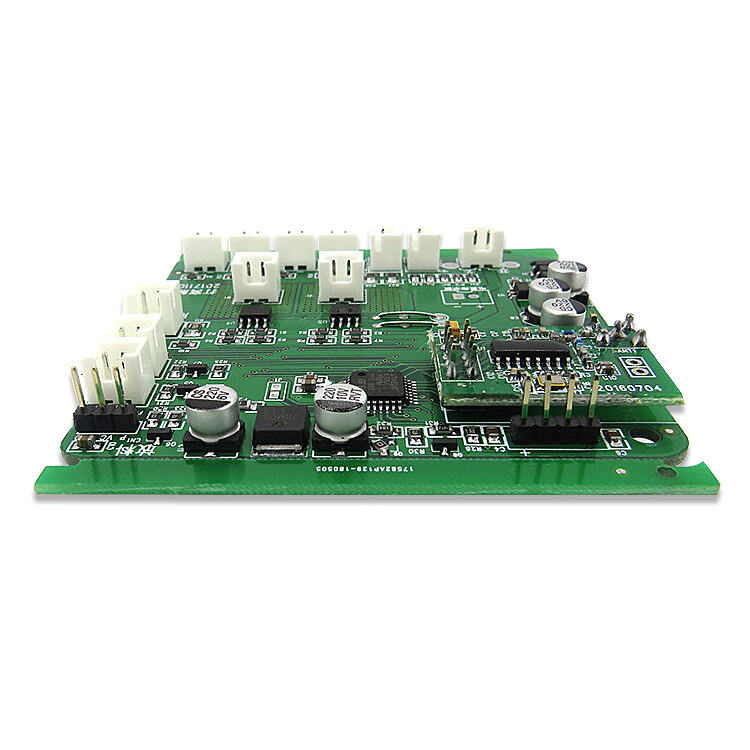

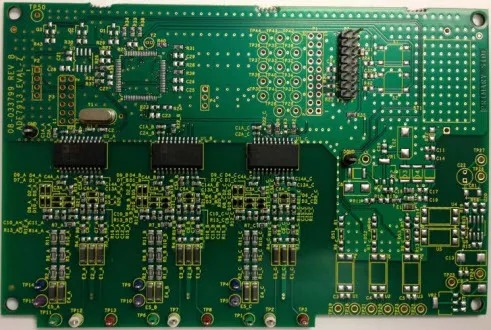

placa de circuito impresso soldada

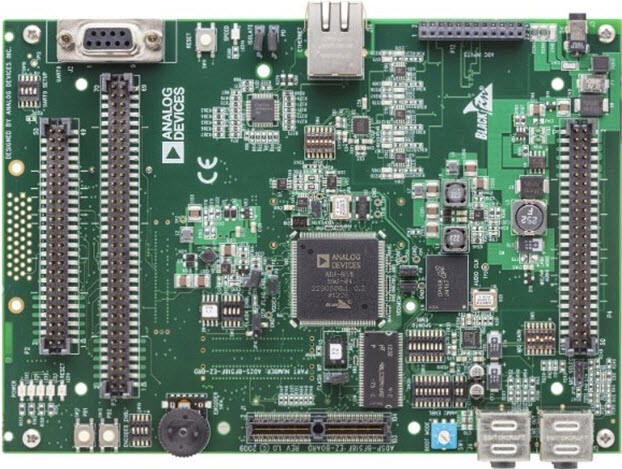

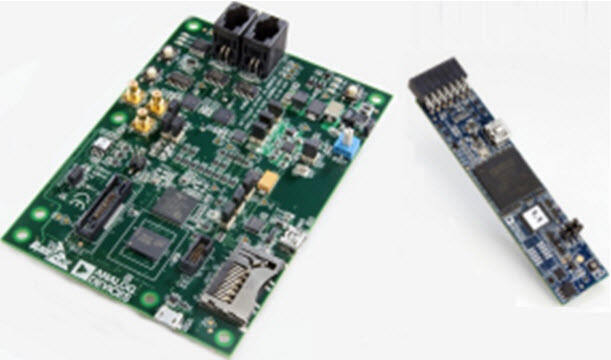

Uma placa de circuito impresso para soldagem é uma ferramenta especializada projetada para a montagem precisa de componentes eletrônicos e fabricação de circuitos. Este equipamento essencial combina sistemas avançados de controle de temperatura com um design ergonômico para facilitar operações de soldagem precisas e eficientes. A placa possui várias zonas de trabalho que acomodam diferentes tamanhos de componentes e requisitos de soldagem, garantindo versatilidade em diversos projetos eletrônicos. Sua superfície é geralmente construída com materiais resistentes a altas temperaturas, capazes de suportar exposição contínua às temperaturas de soldagem sem perder a integridade estrutural. Placas modernas para soldagem incorporam recursos inovadores, como proteção contra estática, ajustes térmicos reguláveis e sistemas de refrigeração integrados para evitar danos aos componentes. Essas placas são fundamentais tanto na fabricação profissional de eletrônicos quanto em projetos caseiros, apoiando processos de soldagem por furo passante e tecnologia de montagem em superfície (SMT). O design frequentemente inclui áreas dedicadas à organização de componentes, aplicação de fluxo e operações de limpeza, otimizando todo o fluxo de trabalho de soldagem. Modelos avançados podem apresentar capacidades integradas de teste para verificar imediatamente a qualidade das conexões e o funcionamento do circuito.