ผู้จัดจำหน่ายแผงวงจรพีซีบีเอ

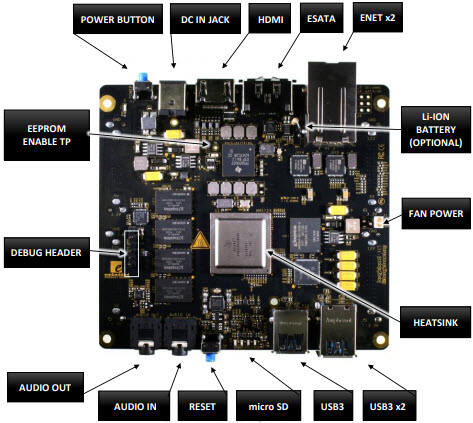

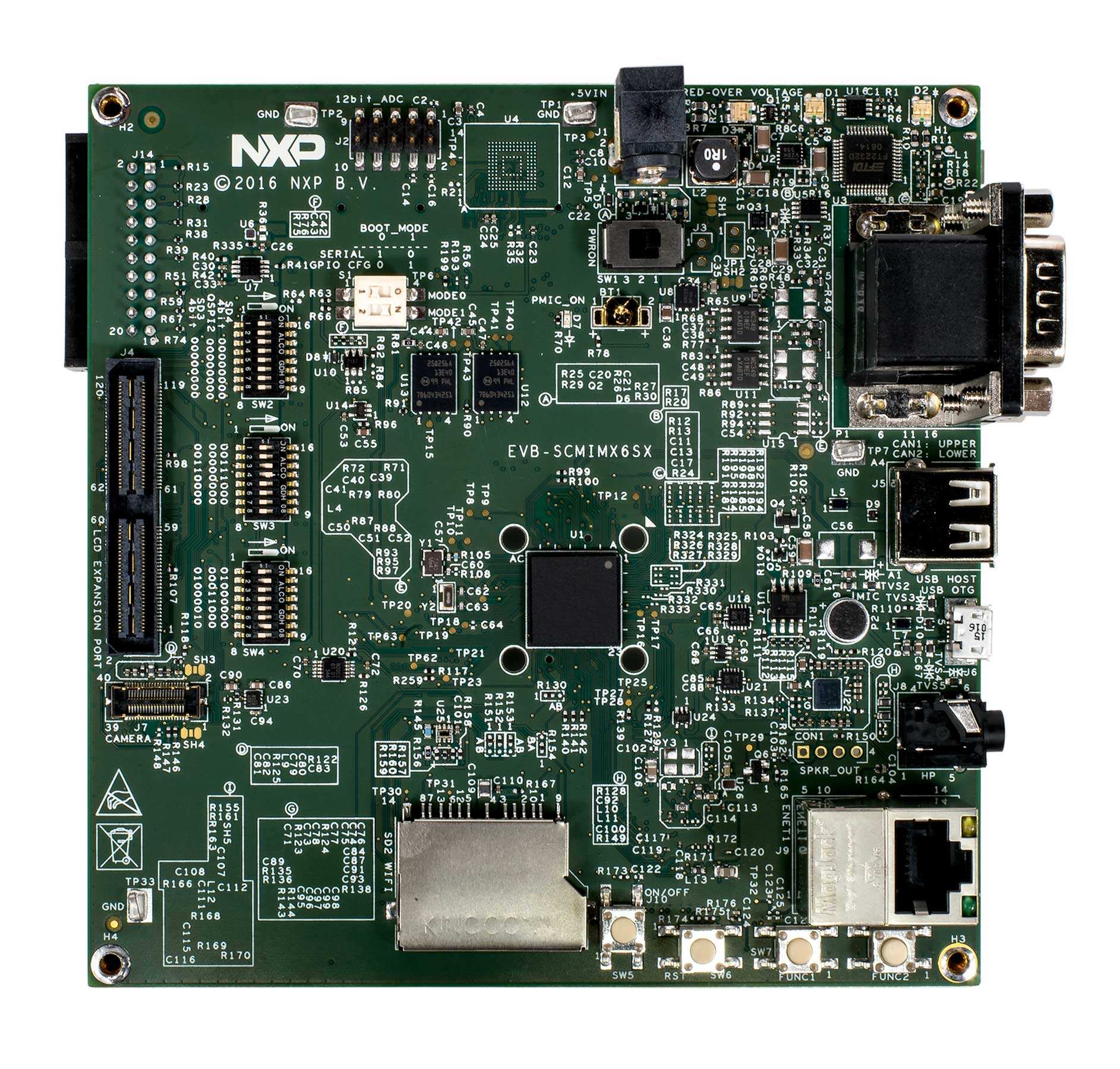

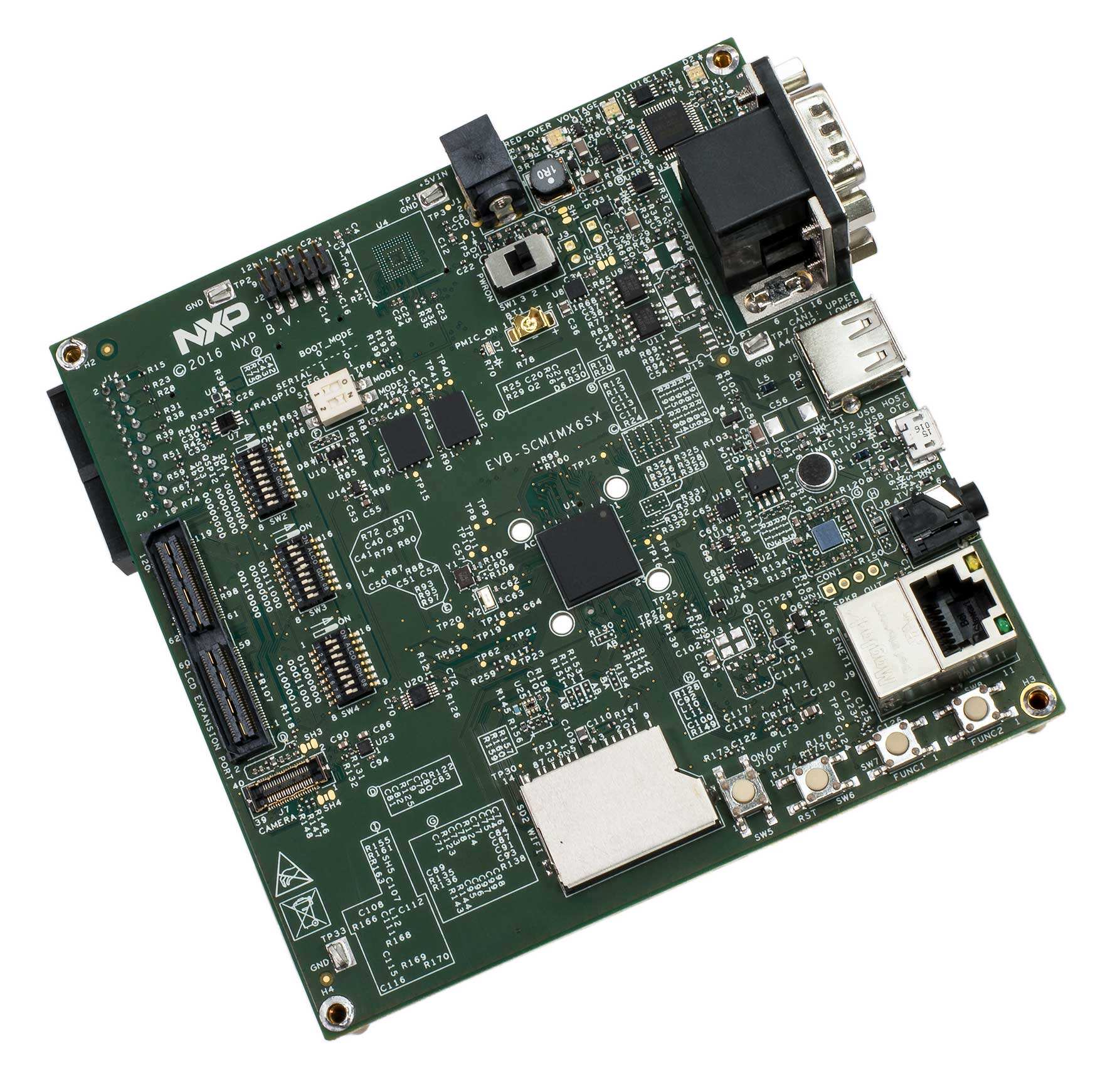

ผู้จัดจำหน่าย PCBA ทำหน้าที่เป็นพันธมิตรที่สำคัญในการผลิตอิเล็กทรอนิกส์ โดยให้บริการประกอบแผงวงจรพิมพ์แบบครบวงจรที่รวมเทคโนโลยีขั้นสูงเข้ากับวิศวกรรมความแม่นยำ ผู้จัดจำหน่ายเหล่านี้มีสิ่งอำนวยความสะดวกที่ทันสมัย พร้อมสายการผลิตเทคโนโลยีการติดตั้งบนพื้นผิวแบบอัตโนมัติ (SMT) ความสามารถในการประกอบแบบผ่านรู และระบบควบคุมคุณภาพขั้นสูง พวกเขาดูแลทุกอย่างตั้งแต่การจัดหาชิ้นส่วน การผลิตแผงวงจรพิมพ์ (PCB) ไปจนถึงการประกอบและการทดสอบอย่างสมบูรณ์ ผู้จัดจำหน่าย PCBA ยุคใหม่ใช้ระบบการดำเนินงานการผลิตขั้นสูง (MES) เพื่อให้มั่นใจในการตรวจสอบการผลิตแบบเรียลไทม์ และรักษามาตรฐานคุณภาพอย่างต่อเนื่อง ความเชี่ยวชาญของพวกเขากว้างขวางครอบคลุมหลายอุตสาหกรรม เช่น อิเล็กทรอนิกส์ยานยนต์ อุปกรณ์ทางการแพทย์ อุปกรณ์โทรคมนาคม และอิเล็กทรอนิกส์สำหรับผู้บริโภค ผู้จัดจำหน่ายเหล่านี้มักจะให้บริการทั้งการผลิตต้นแบบและผลิตในปริมาณมาก สนับสนุนลูกค้าตั้งแต่ขั้นตอนการออกแบบเริ่มต้นไปจนถึงการผลิตจำนวนมาก นอกจากนี้ยังคงปฏิบัติตามมาตรฐานสากลอย่างเคร่งครัด เช่น ISO 9001 มาตรฐาน IPC และข้อกำหนด RoHS เพื่อให้มั่นใจถึงคุณภาพและความน่าเชื่อถือสูงสุดของแผงวงจรที่ประกอบขึ้น ความสามารถด้านเทคนิกรวมถึงการวางชิ้นส่วนระยะห่างแคบ การซ่อมแซม BGA การบัดกรีแบบคัดสรร และบริการทดสอบอย่างครอบคลุม ได้แก่ AOI การตรวจสอบด้วยรังสีเอกซ์ และการทดสอบการทำงาน