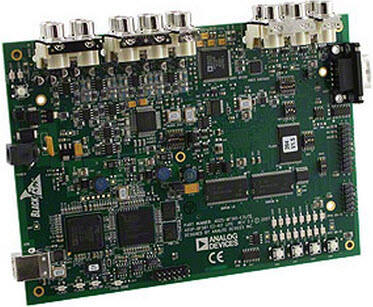

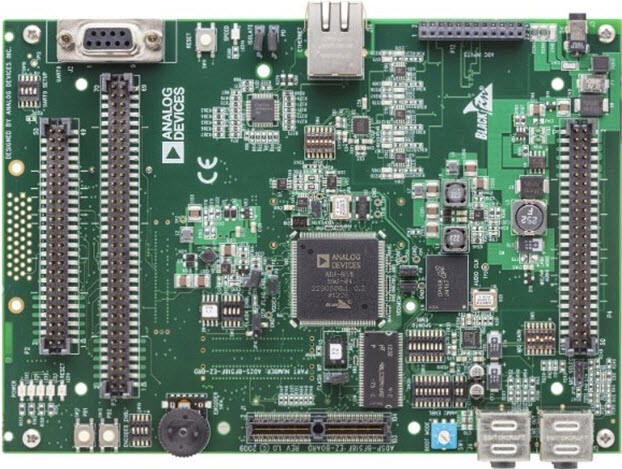

double sided pcb board

A double sided PCB board represents a significant advancement in electronic circuit design, featuring conductive copper layers on both the top and bottom surfaces of the substrate. This configuration enables more complex circuit designs and higher component density compared to single sided boards. The board's construction typically consists of a core material, usually FR4, with copper layers bonded to both sides, connected through plated through holes or vias. These interconnections allow electrical signals to travel between the two sides, creating more efficient routing possibilities and enhanced functionality. Double sided PCB boards have become essential in modern electronics, supporting applications ranging from consumer electronics to industrial automation systems. They offer improved signal integrity, better electromagnetic shielding, and more efficient use of space. The manufacturing process involves precise layering, drilling, plating, and etching techniques to ensure reliable connections between components. These boards can accommodate surface mount devices (SMD) and through hole components on both sides, maximizing design flexibility and circuit density. The presence of ground planes on either side also contributes to better electrical performance and reduced electromagnetic interference.