low cost pcba

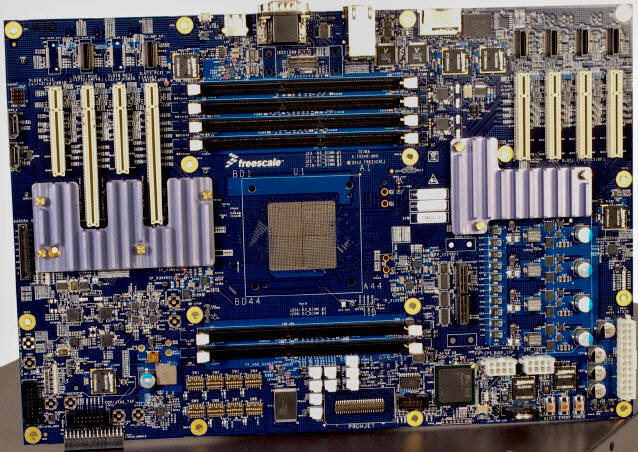

Low cost PCBA (Printed Circuit Board Assembly) represents a cost-effective solution for electronic manufacturing that maintains quality while reducing production expenses. This manufacturing approach combines efficient component placement, automated assembly processes, and strategic material sourcing to deliver reliable circuit boards at competitive prices. The technology incorporates surface mount technology (SMT) and through-hole mounting techniques, enabling the creation of complex electronic assemblies for various applications. These assemblies are produced using advanced pick-and-place machines, reflow soldering systems, and automated optical inspection equipment to ensure consistent quality. Low cost PCBAs are particularly valuable in consumer electronics, industrial controls, automotive components, and IoT devices. The manufacturing process emphasizes bulk production efficiency while maintaining strict quality control measures, including automated testing procedures and environmental stress screening. These assemblies can accommodate both simple and multilayer designs, supporting various component densities and complexity levels while keeping costs manageable. The production methodology includes strategic component selection, optimized layout design, and efficient assembly processes that reduce waste and maximize yield rates.