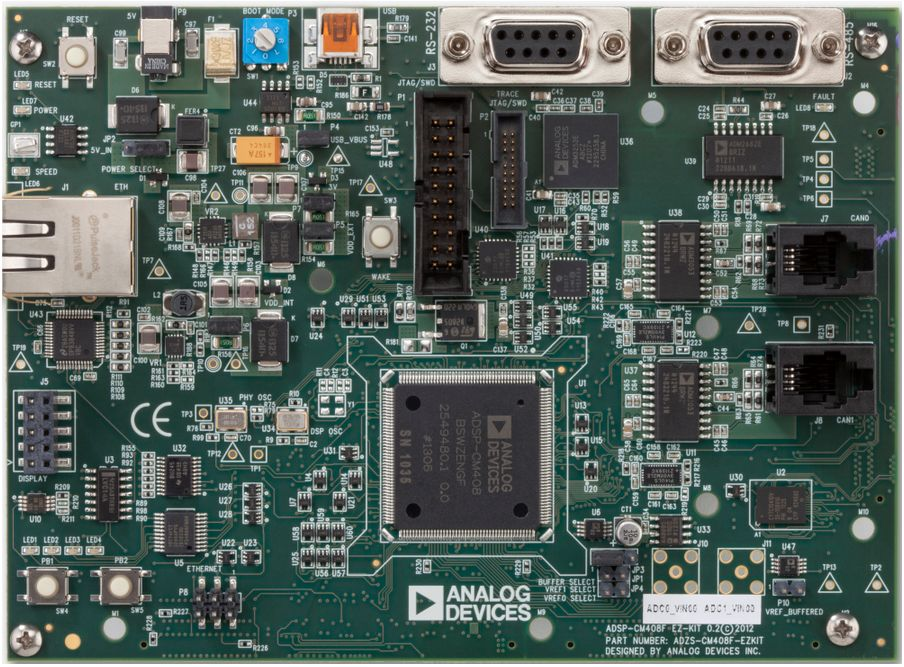

prototype pcb assembly

Prototype PCB assembly represents a crucial phase in electronics development, combining advanced manufacturing techniques with precision engineering to create functional circuit board prototypes. This process involves the careful placement and soldering of electronic components onto printed circuit boards, allowing designers and engineers to test and validate their designs before moving to full-scale production. The assembly incorporates state-of-the-art surface mount technology (SMT) and through-hole mounting techniques, ensuring compatibility with various component types and design specifications. These prototypes serve as essential tools for identifying potential design flaws, optimizing performance parameters, and verifying electrical connectivity. The assembly process utilizes automated pick-and-place machines alongside manual assembly methods, offering flexibility in component placement and enabling rapid iterations of design modifications. This versatility makes prototype PCB assembly invaluable across multiple industries, from consumer electronics to aerospace applications, supporting both simple and complex circuit designs with multiple layers and sophisticated routing solutions.