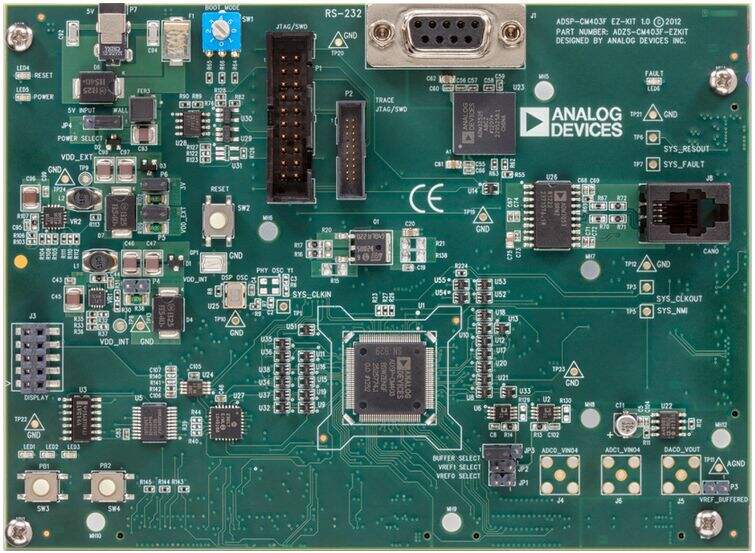

pcb sensors

PCB sensors represent a cutting-edge advancement in sensing technology, integrating sophisticated measurement capabilities directly into printed circuit boards. These specialized sensors are designed to detect and monitor various physical parameters including temperature, pressure, vibration, and electromagnetic fields. The compact design allows for seamless integration into existing electronic systems while maintaining high precision and reliability. PCB sensors utilize advanced microelectronic fabrication techniques to create sensing elements that are directly embedded within the circuit board structure, enabling multiple sensing functions within a single component. These sensors excel in applications requiring precise measurements in confined spaces, such as industrial automation, automotive systems, consumer electronics, and medical devices. The technology behind PCB sensors combines traditional sensing principles with modern PCB manufacturing processes, resulting in cost-effective and highly reliable sensing solutions. Their ability to withstand harsh environmental conditions while maintaining accuracy makes them ideal for demanding applications. Furthermore, PCB sensors often incorporate digital signal processing capabilities, allowing for real-time data analysis and immediate response to environmental changes.