pcb de alta corriente

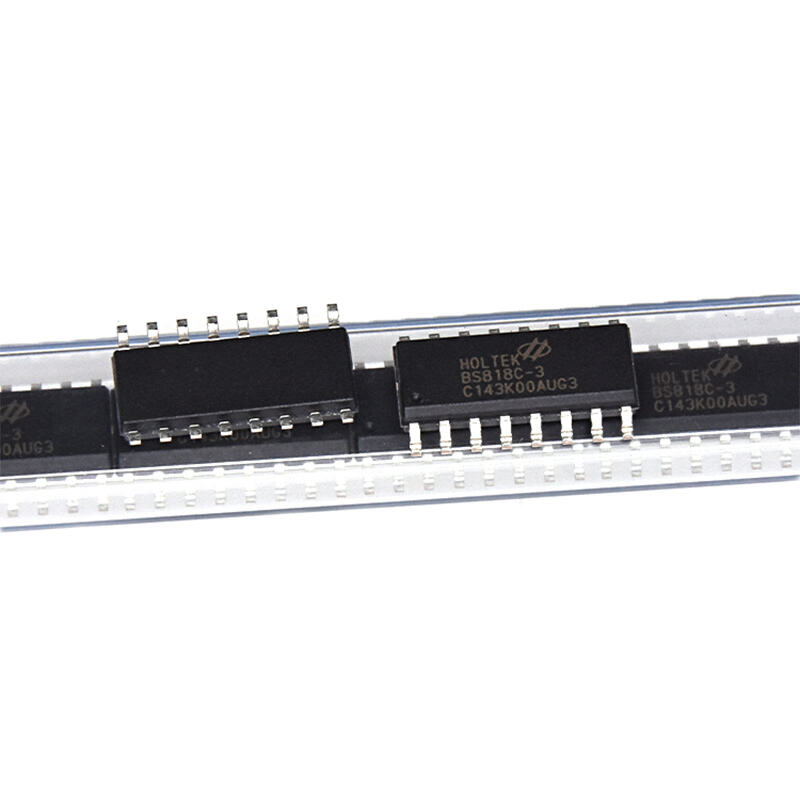

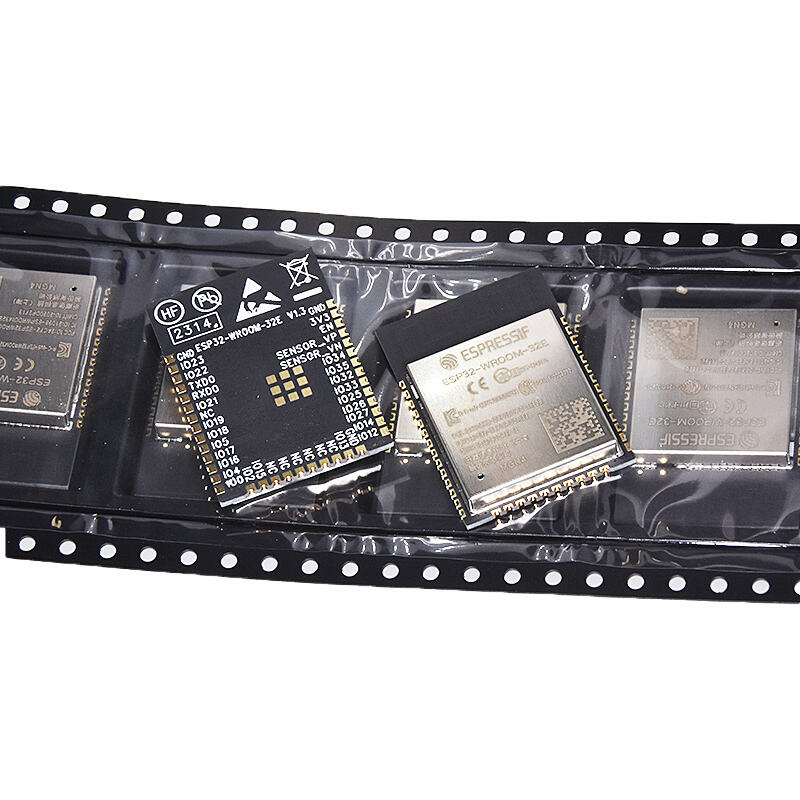

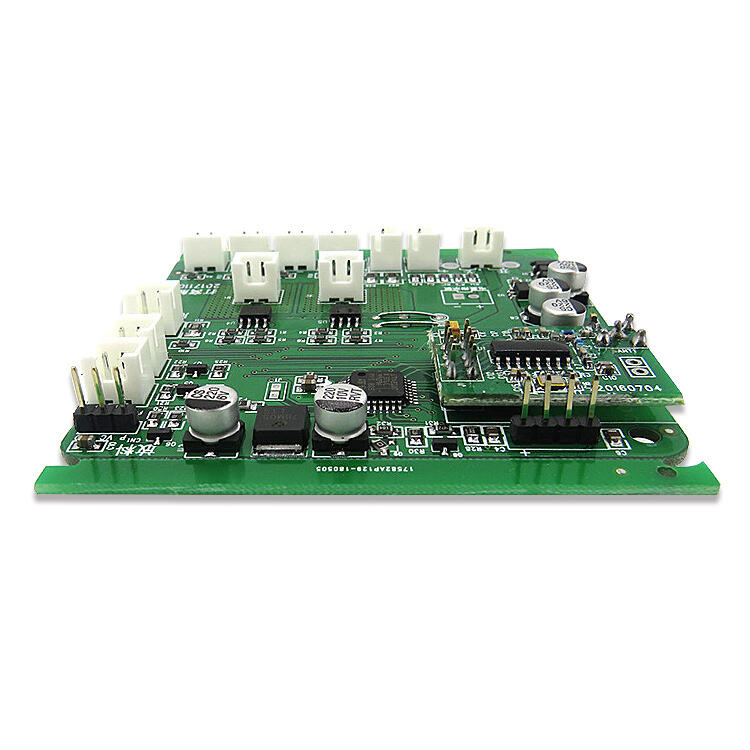

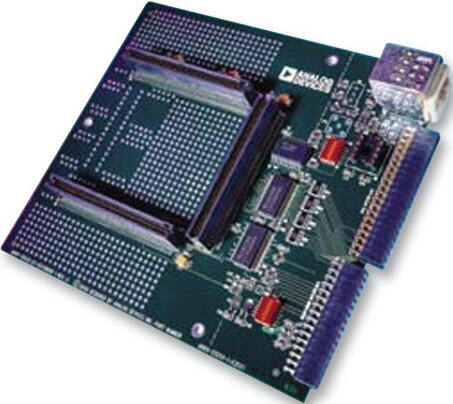

Los PCB de alta corriente representan una categoría especializada de placas de circuito impreso diseñadas para manejar corrientes eléctricas sustanciales manteniendo un rendimiento y seguridad óptimos. Estas placas avanzadas incorporan trazas de cobre más gruesas, capacidades mejoradas de gestión térmica y una construcción robusta para soportar aplicaciones de alta potencia. Las placas suelen incluir pesos de cobre que van desde 2 oz hasta 12 oz, significativamente más altos que los de los PCB estándar, lo que les permite gestionar corrientes superiores a 100 amperios. Entre sus características tecnológicas clave se encuentran vías térmicas especializadas, múltiples capas de cobre y materiales avanzados de sustrato que facilitan una disipación eficiente del calor. Los PCB de alta corriente tienen amplias aplicaciones en fuentes de alimentación, controladores de motores, sistemas de iluminación LED e instalaciones de energía renovable. Su diseño incorpora redes sofisticadas de distribución de energía, asegurando una caída mínima de voltaje y una capacidad máxima de conducción de corriente. Estas placas suelen utilizar técnicas avanzadas de fabricación, como el galvanizado selectivo y el control preciso de impedancia, para mantener la integridad de la señal incluso bajo condiciones de alta corriente. La integración de soluciones de gestión térmica, incluyendo planos de cobre y una colocación estratégica de componentes, garantiza un funcionamiento confiable en entornos exigentes.