solución pcba

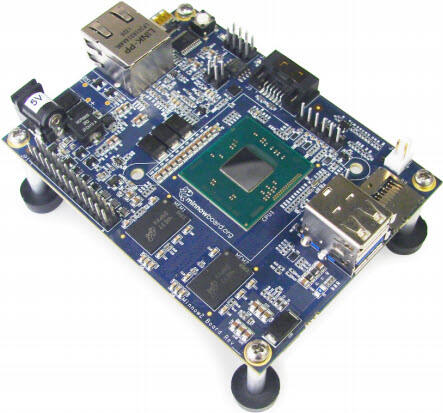

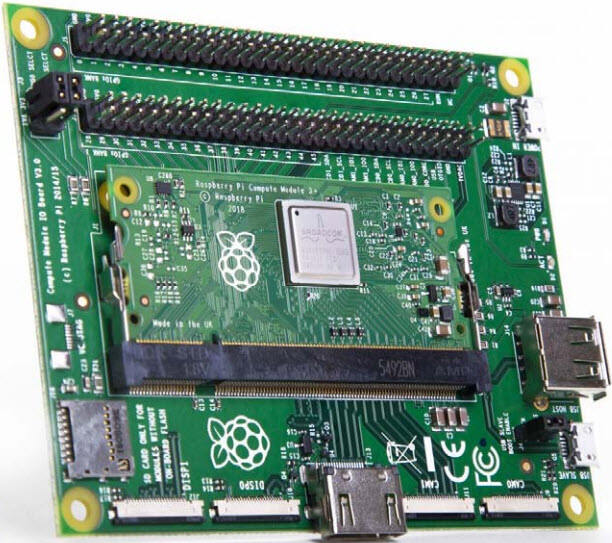

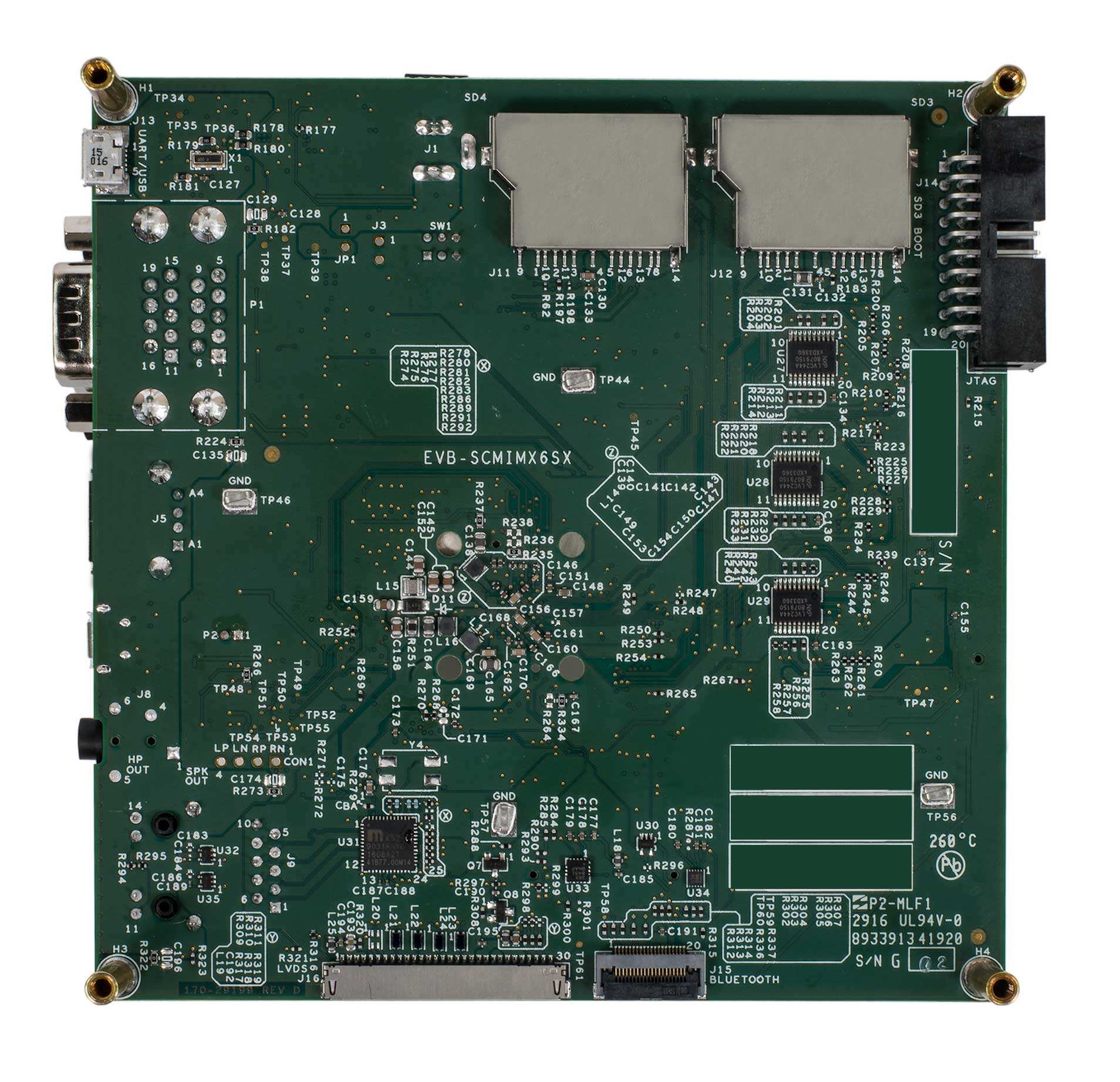

Las soluciones PCBA (ensamblaje de placas de circuito impreso) representan un enfoque integral para la fabricación electrónica, combinando tecnología de vanguardia con ingeniería de precisión. Esta solución integrada abarca todo el proceso de transformar PCBs básicas en ensamblajes electrónicos completamente funcionales. La solución incorpora tecnologías avanzadas de montaje superficial (SMT) y técnicas de ensamblaje por orificio pasante, asegurando una colocación óptima de los componentes y una calidad superior en las soldaduras. Las medidas de control de calidad están integradas a lo largo de todo el proceso de fabricación, incluyendo sistemas de inspección óptica automática (AOI) y de rayos X que verifican la colocación de los componentes y la integridad de las uniones soldadas. La solución también incluye protocolos de pruebas sofisticados, desde pruebas de circuito en línea hasta pruebas funcionales, garantizando la fiabilidad de los ensamblajes terminados. Se mantienen controles ambientales y medidas de protección contra descargas electrostáticas (ESD) en todo el entorno de producción, protegiendo los componentes electrónicos sensibles. Sistemas avanzados de planificación de producción y gestión de materiales aseguran un flujo de trabajo eficiente y la disponibilidad de componentes, mientras que el monitoreo en tiempo real y la recopilación de datos permiten mejoras continuas en los procesos y trazabilidad completa.