pcba conforme con RoHS

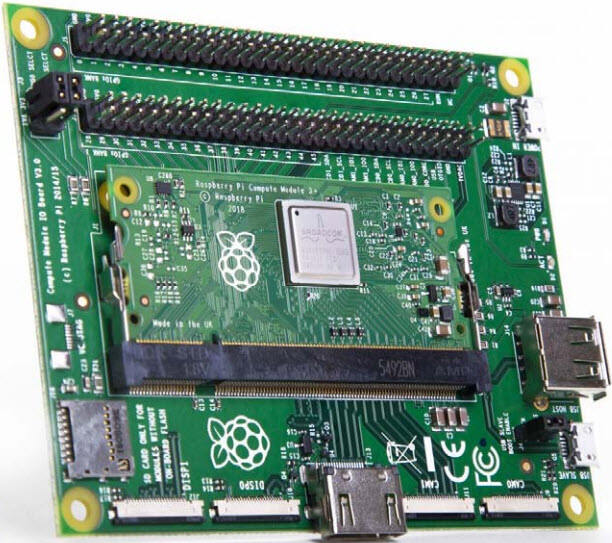

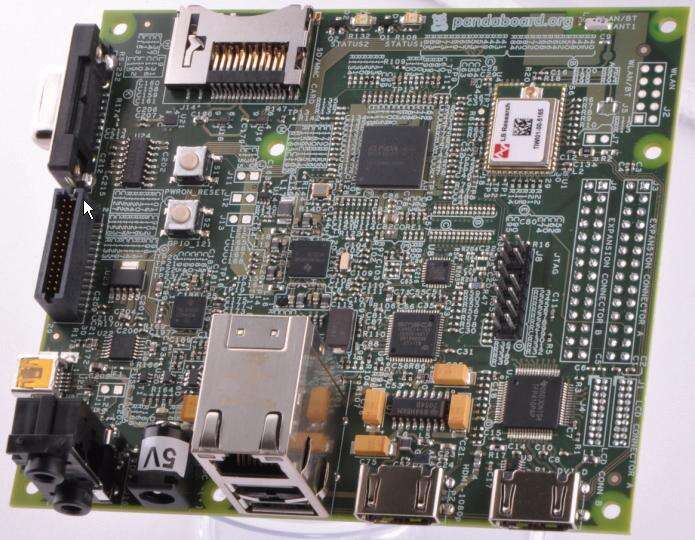

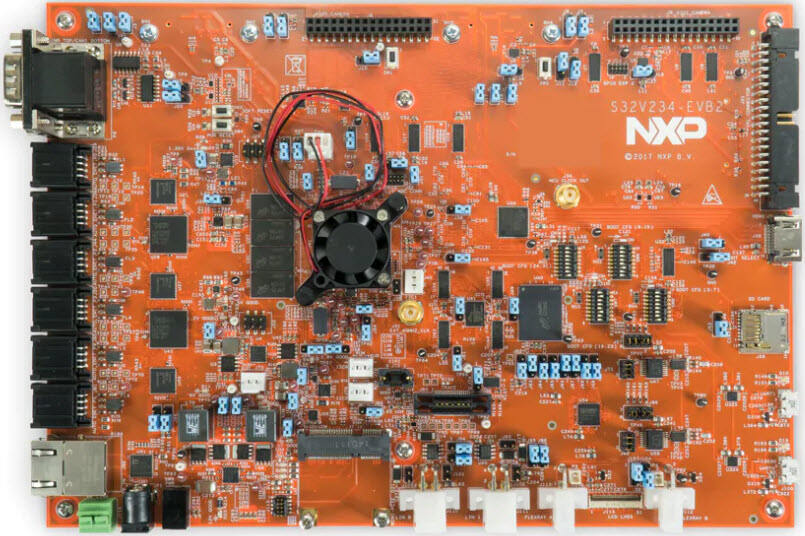

Un PCBA (ensamblaje de placa de circuito impreso) conforme a RoHS representa un avance significativo en la fabricación electrónica consciente del medio ambiente. Estos ensamblajes se fabrican estrictamente según la directiva sobre la restricción de sustancias peligrosas (RoHS), garantizando la ausencia de materiales nocivos como plomo, mercurio, cadmio, cromo hexavalente, bifenilos polibromados y éteres difenilos polibromados. El proceso de fabricación utiliza soldadura libre de plomo y componentes que cumplen con rigurosos estándares ambientales, manteniendo al mismo tiempo un rendimiento y fiabilidad óptimos. Los PCBAs conformes a RoHS sirven como base de dispositivos electrónicos modernos, incorporando diseños de circuitos sofisticados que soportan diversas aplicaciones, desde electrónica de consumo hasta sistemas de automatización industrial. Estos ensamblajes integran tecnología avanzada de montaje superficial y componentes de inserción, permitiendo un diseño compacto mientras aseguran conexiones eléctricas robustas. La certificación de conformidad garantiza que los PCBAs cumplan con las regulaciones ambientales internacionales, haciéndolos adecuados para su distribución en mercados globales. Demuestran una estabilidad térmica, conductividad eléctrica y durabilidad mecánica excepcionales, todo ello minimizando el impacto ambiental. Estos ensamblajes son sometidos a pruebas exhaustivas de fiabilidad y rendimiento, asegurando que cumplan con los exigentes requisitos de las aplicaciones electrónicas modernas, a la vez que respetan normas ecológicas.