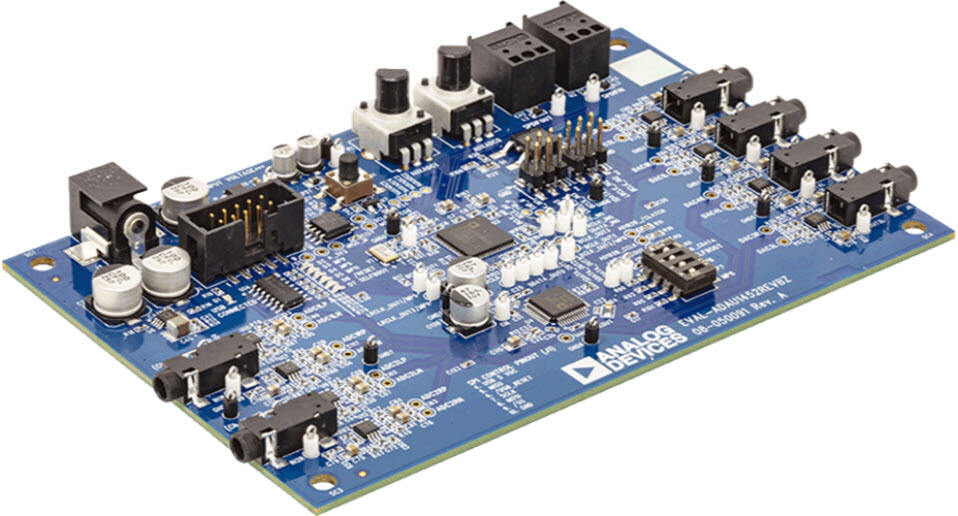

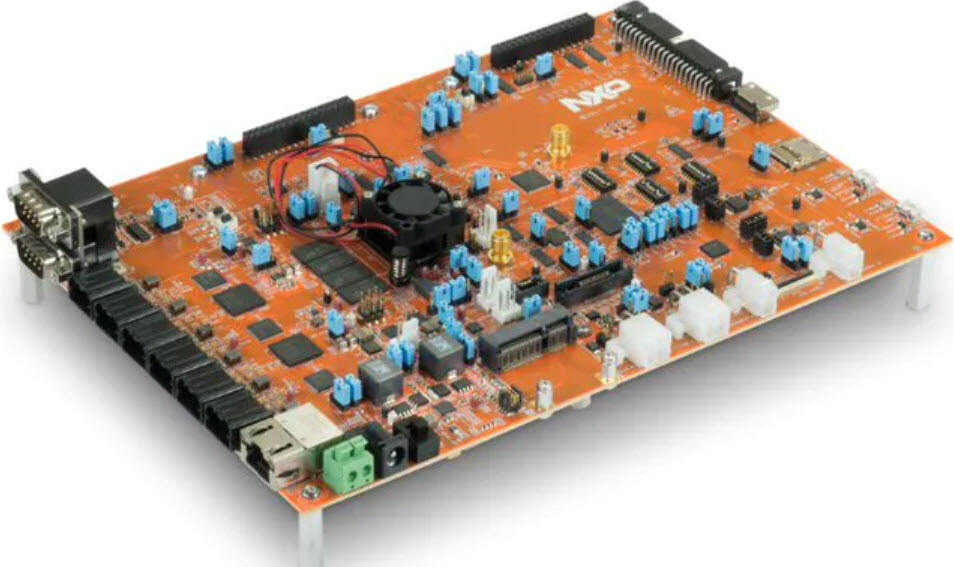

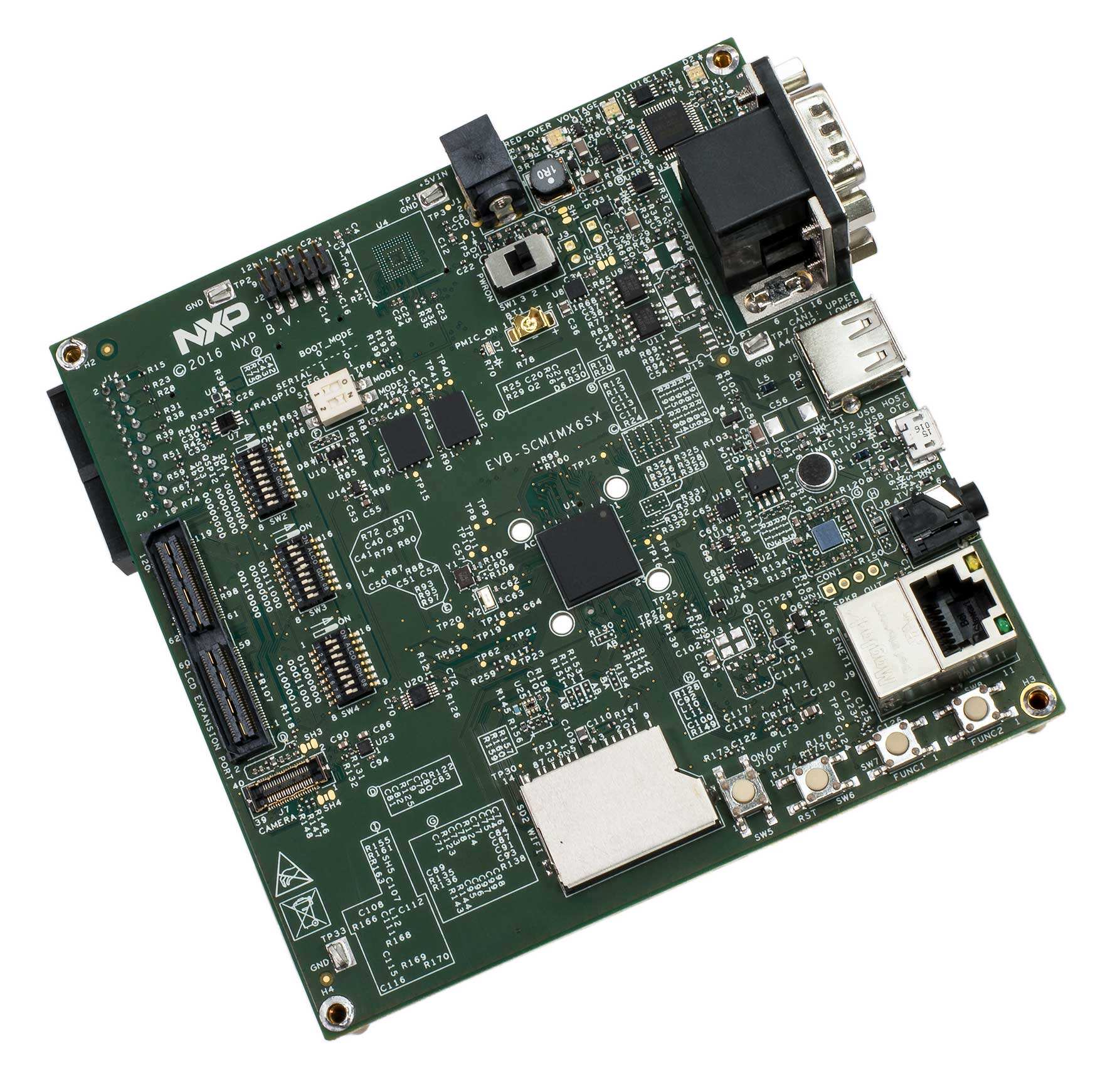

pcba board

A PCBA (Printed Circuit Board Assembly) board represents the cornerstone of modern electronic devices, serving as an intricate assembly where electronic components are soldered onto a printed circuit board. This sophisticated piece of technology integrates various elements including resistors, capacitors, integrated circuits, and microprocessors into a single functional unit. The manufacturing process involves precise surface mount technology (SMT) and through-hole assembly techniques, ensuring optimal component placement and electrical connectivity. PCBA boards are designed to provide reliable electrical connections, signal distribution, and power management while maintaining compact dimensions and efficient heat dissipation. These boards serve as the backbone for countless electronic devices, from consumer electronics to industrial equipment, medical devices, and automotive systems. The versatility of PCBA boards allows for customization according to specific applications, with different layer counts, component densities, and circuit complexities available to meet diverse requirements. Modern PCBA boards often incorporate advanced features such as impedance control, electromagnetic interference (EMI) protection, and thermal management solutions, making them essential for high-performance electronic systems.