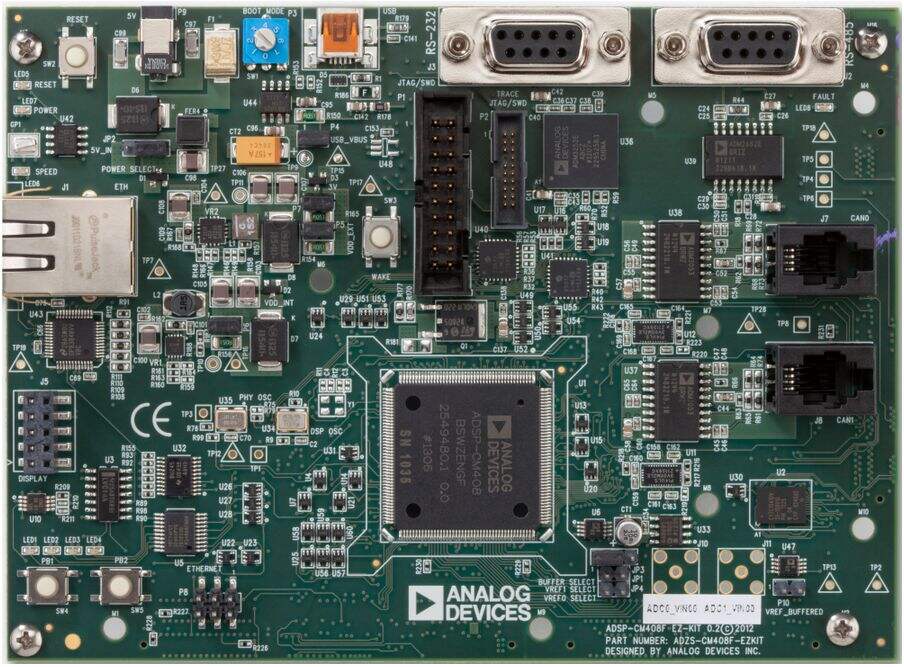

usine de PCB

Une usine de PCB représente une installation de fabrication de pointe dédiée à la production de cartes de circuits imprimés qui constituent la colonne vertébrale de l'électronique moderne. Ces installations ultramodernes intègrent des systèmes d'automatisation avancés, des équipements de précision et des mesures strictes de contrôle qualité afin d'assurer une production de PCB constante et de haute qualité. L'usine comprend généralement plusieurs départements spécialisés, notamment la vérification de conception, la préparation des matériaux, l'impression des circuits, la gravure, les tests et l'assemblage final. Les procédés de fabrication avancés utilisent des équipements commandés par ordinateur pour un alignement précis des couches, des systèmes d'inspection optique automatisés pour garantir la qualité, ainsi que des systèmes de contrôle environnemental maintenant des niveaux optimaux de température et d'humidité. Ces installations peuvent produire différents types de PCB, allant des simples couches aux cartes multicouches complexes, en utilisant divers matériaux et spécifications selon les exigences des clients. La chaîne de production intègre des technologies sophistiquées telles que le perçage au laser, l'application automatique du masque de soudure et le traitement des finitions de surface, assurant un positionnement précis des composants et des connexions électriques fiables. Les usines modernes de PCB mettent également l'accent sur la responsabilité environnementale grâce à des systèmes de gestion des déchets et à des opérations écoénergétiques, tout en respectant les normes et certifications internationales de fabrication.