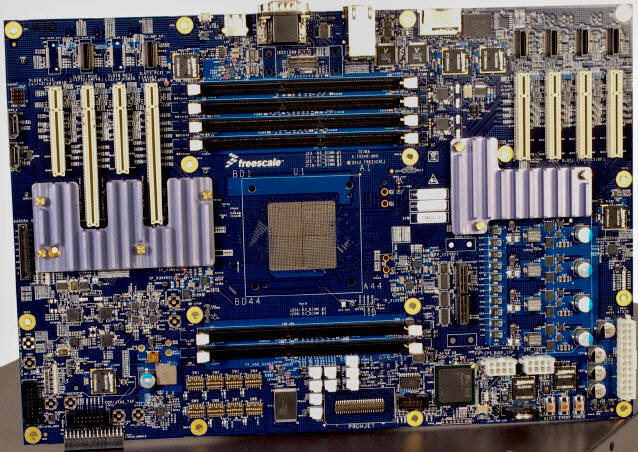

저비용 PCBA

저비용 PCBA(Printed Circuit Board Assembly)는 품질을 유지하면서 생산 비용을 절감할 수 있는 전자제조 분야의 경제적인 솔루션입니다. 이 제조 방식은 효율적인 부품 배치, 자동 조립 공정 및 전략적 소재 조달을 결합하여 경쟁력 있는 가격으로 신뢰성 높은 회로 기판을 제공합니다. 해당 기술은 표면 실장 기술(SMT)과 스루홀 마운팅 기법을 포함하여 다양한 응용 분야에 사용되는 복잡한 전자 어셈블리를 제작할 수 있게 해줍니다. 이러한 어셈블리는 첨단 피크앤플레이스 장비, 리플로우 납땜 시스템 및 자동 광학 검사 장비를 사용해 일관된 품질을 보장하며 제조됩니다. 저비용 PCBA는 특히 소비자 가전 제품, 산업용 컨트롤러, 자동차 부품 및 사물인터넷(IoT) 기기에서 큰 가치를 지닙니다. 제조 공정은 대량 생산 효율성을 강조하면서도 자동화된 테스트 절차와 환경 스트레스 검사 등을 포함한 엄격한 품질 관리 기준을 유지합니다. 이러한 어셈블리는 단순한 설계부터 다층 기판 설계까지 모두 지원하며 다양한 부품 밀도와 복잡성 수준을 수용하되 비용은 관리 가능한 수준으로 유지합니다. 생산 방법론에는 전략적인 부품 선정, 최적화된 레이아웃 설계 및 폐기물을 줄이고 수율을 극대화하는 효율적인 조립 공정이 포함됩니다.