pCBA 부품

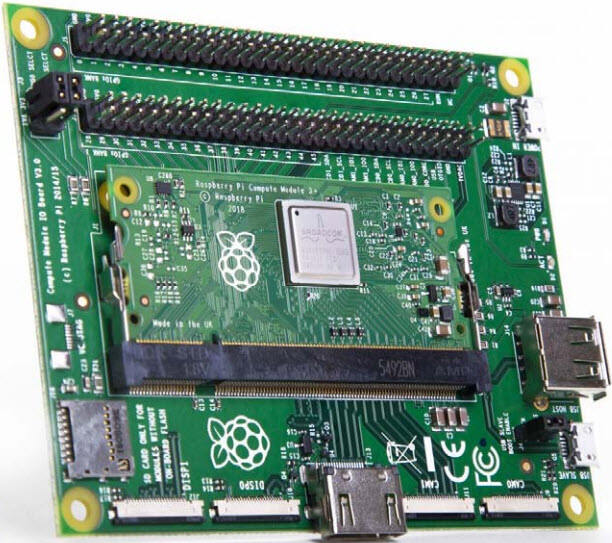

인쇄 회로 기판 어셈블리(PCBA)는 모든 부품이 PCB에 납땜된 후의 완성된 회로 기판을 의미하며, 현대 전자기기에서 핵심적인 구성 요소입니다. 이 정교한 어셈블리는 집적회로, 저항, 커패시터, 커넥터 등 다양한 전자 부품을 통합하여 완전한 기능을 갖춘 전자 시스템을 구현합니다. PCBA는 전도성 경로를 통해 부품 간의 기계적 지지와 전기적 연결을 제공함으로써 전자 장치의 중심 역할을 합니다. 이러한 경로는 구리 시트를 에칭하여 형성됩니다. 제조 공정에는 정밀한 부품 배치와 납땜 기술이 포함되어 신뢰할 수 있는 전기적 연결과 최적의 성능을 보장합니다. 어셈블리는 회로 설계 및 응용 분야의 복잡성에 따라 단면 또는 다층 구조일 수 있습니다. PCBA는 소비자용 전자 제품부터 산업 장비, 의료 기기, 항공우주 응용 분야에 이르기까지 다양한 분야에서 필수적입니다. PCBA 제조 기술은 자동화된 어셈블리 공정, 표면 실장 기술(SMT), 스루홀 실장 기술 등을 도입하며 크게 발전해 왔습니다. 자동 광학 검사(AOI) 및 기능 테스트와 같은 품질 관리 절차를 통해 각 어셈블리가 엄격한 성능 및 신뢰성 기준을 충족하도록 합니다. PCBA의 유연성 덕분에 크기, 복잡성, 기능성 측면에서 맞춤화가 가능하여 현대 전자 설계 및 제조에서 없어서는 안 될 존재가 되었습니다.