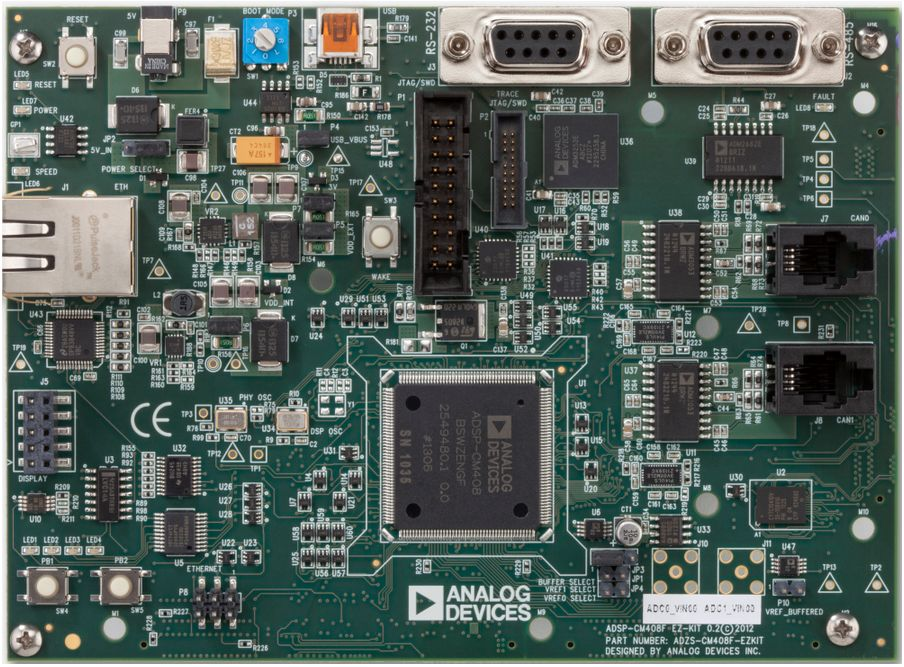

montagem de pcb de protótipo

A montagem de protótipos de PCB representa uma fase crucial no desenvolvimento eletrônico, combinando técnicas avançadas de fabricação com engenharia de precisão para criar protótipos funcionais de placas de circuito. Esse processo envolve a colocação cuidadosa e soldagem de componentes eletrônicos em placas de circuito impresso, permitindo que projetistas e engenheiros testem e validem seus designs antes de avançar para a produção em larga escala. A montagem incorpora tecnologias modernas de montagem em superfície (SMT) e técnicas de montagem com furo passante, garantindo compatibilidade com diversos tipos de componentes e especificações de projeto. Esses protótipos atuam como ferramentas essenciais para identificar possíveis falhas de design, otimizar parâmetros de desempenho e verificar a conectividade elétrica. O processo de montagem utiliza máquinas automatizadas de pick-and-place aliadas a métodos manuais de montagem, oferecendo flexibilidade na colocação de componentes e permitindo rápidas iterações de modificações de projeto. Essa versatilidade torna a montagem de protótipos de PCB extremamente valiosa em múltiplos setores, desde eletrônicos de consumo até aplicações aeroespaciais, suportando designs tanto simples quanto complexos, com múltiplas camadas e soluções sofisticadas de roteamento.