ความสามารถในการจัดการความร้อนขั้นสูง

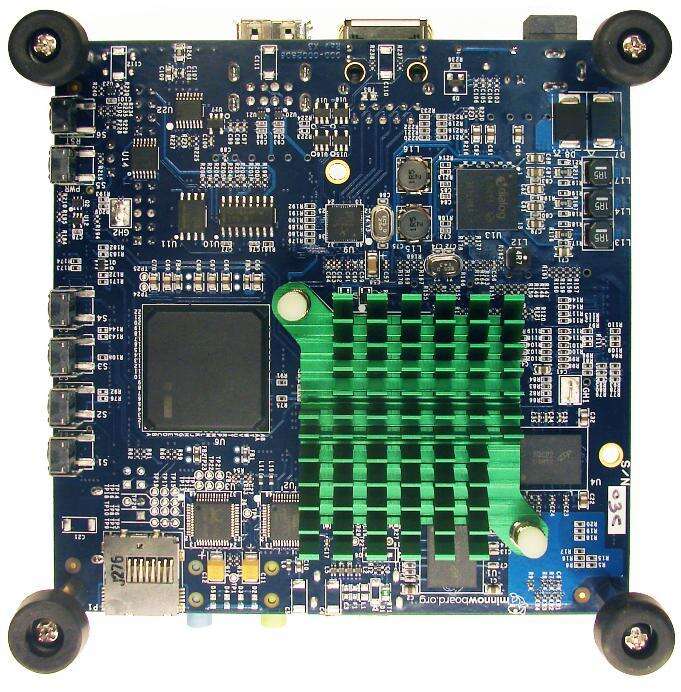

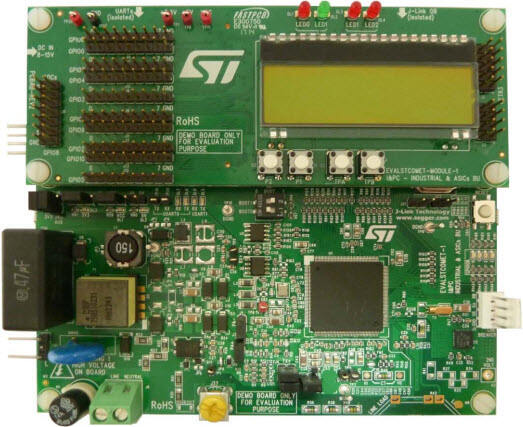

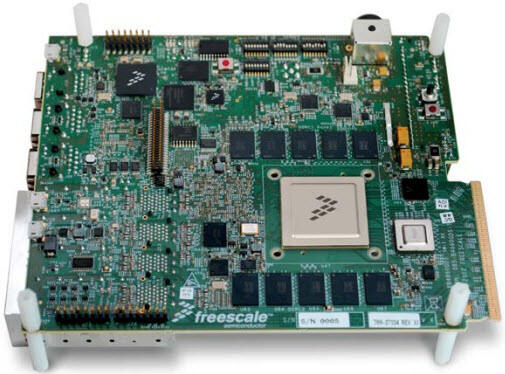

แผงวงจรพิมพ์แข็ง (Rigid PCBAs) มีข้อได้เปรียบด้านการจัดการความร้อนอันเนื่องมาจากโครงสร้างหลายชั้นที่ซับซ้อนและคุณสมบัติของวัสดุ ความสามารถในการรวมระนาบถ่ายเทความร้อน (thermal planes) และไวด์ (vias) ทำให้สามารถกระจายความร้อนจากส่วนประกอบที่ใช้พลังงานสูงได้อย่างมีประสิทธิภาพ ชั้นทองแดงภายในบอร์ดทำหน้าที่เป็นตัวกระจายความร้อนที่ดีเยี่ยม โดยช่วยกระจายพลังงานความร้อนไปทั่วทั้งชิ้นส่วน เพื่อป้องกันไม่ให้เกิดจุดร้อนเฉพาะที่ ความสามารถในการจัดการความร้อนนี้มีความสำคัญอย่างยิ่งต่อการรักษาอุณหภูมิการทำงานที่เหมาะสม ซึ่งส่งผลโดยตรงต่อความน่าเชื่อถือและประสิทธิภาพของชิ้นส่วน อีกทั้งโครงสร้างแบบแข็งยังช่วยให้สามารถใช้วิธีการจัดการความร้อนต่างๆ ได้ เช่น thermal vias, heat sinks และ cooling planes ซึ่งให้ทางเลือกแก่นักออกแบบในการแก้ไขปัญหาด้านความร้อนเฉพาะเจาะจง คุณลักษณะนี้มีความสำคัญอย่างยิ่งในแอปพลิเคชันที่ใช้กำลังไฟสูง ซึ่งการถ่ายเทความร้อนอย่างมีประสิทธิภาพมีบทบาทสำคัญในการป้องกันความเสียหายจากความร้อนและรับประกันประสิทธิภาพที่คงที่