yüksek hızlı pcb

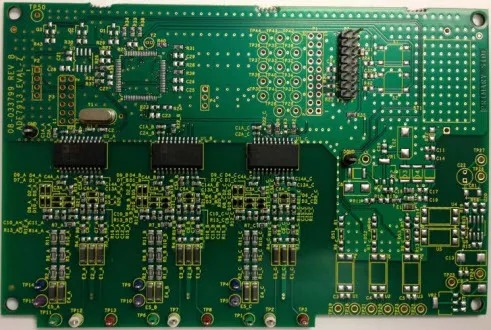

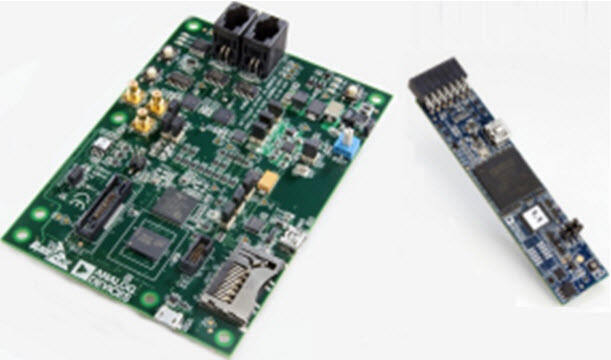

Yüksek hızlı PCB (Baskılı Devre Kartı), özellikle yüksek frekanslarda ve hızlı veri iletim hızlarında sinyal bütünlüğünü korumak üzere tasarlanmış, elektronik devre tasarımında keskin uçlu bir gelişmedir. Bu karmaşık kartlar, tipik olarak 500 MHz'den birkaç GHz'e kadar değişen frekansları yönetebilmek için özel malzemelerle ve hassas tasarım dikkatleriyle üretilir. Yapımında, sinyal kaybını ve gürültüyü en aza indirmek amacıyla çok katmanlı yüksek performanslı dielektrik malzemeler, dikkatle kontrol edilmiş empedans yolları ve gelişmiş yüzey kaplamaları kullanılır. Yüksek hızlı PCB'ler, empedans uyumu, uygun topraklama düzlemleri ve optimum sinyal iletimini sağlamak için dikkatle hesaplanmış iz genişlikleri gibi kritik özellikleri içerir. Hızlı veri aktarımı gerektiren modern elektronik uygulamalarda, özellikle telekomünikasyon ekipmanları, yüksek performanslı bilgisayar sistemleri ve gelişmiş ağ cihazlarında hayati öneme sahip bileşenlerdir. Tasarım süreci, elektromanyetik girişim (EMI), komşu izler arasındaki sinyal karışımı ve sinyal yansıması gibi faktörleri dikkate alır ve sinyal bütünlüğünü korumak için diferansiyel çift yönlendirme ve uygun katman yapısı tasarımı gibi gelişmiş teknikler kullanır. Bu kartlar, yüksek frekanslı uygulamalarda performansı ve güvenilirliği artırmak için genellikle özel yüzey kaplamaları ve bakır kalınlıklarıyla donatılmıştır.