In modern industrial systems, the reliability of electronic components is a key determinant of operational efficiency, safety, and long-term cost control. Printed Circuit Board Assemblies (PCBA) form the backbone of industrial devices, from automation controllers to power management modules. Selecting a reliable PCBA is critical because industrial environments often subject electronics to extreme temperatures, vibration, dust, and electrical interference. A high-quality PCBA ensures stable performance, reduces maintenance downtime, and supports continuous operation in demanding industrial applications.

Reliable PCBA for industrial applications must meet recognized quality standards such as IPC-A-610, ISO 9001, or specific environmental certifications. These standards cover soldering quality, component placement accuracy, and overall assembly integrity. Ensuring compliance helps prevent failures due to poor connections or defective components.

The quality of components used in a PCBA directly impacts durability and performance. Industrial PCBA should use components rated for extended temperature ranges, high humidity tolerance, and vibration resistance. Choosing high-quality resistors, capacitors, semiconductors, and connectors ensures that the PCBA can withstand harsh industrial conditions.

Industrial PCBA often operates under high loads, generating significant heat. Proper thermal design, including heat sinks, thermal vias, and copper planes, helps maintain stable performance. Effective thermal management extends the lifespan of both the PCBA and the devices it powers.

Industrial environments are prone to electromagnetic interference (EMI) and electrical noise. Reliable PCBA designs incorporate proper grounding, shielding, and trace routing to preserve signal integrity. This ensures accurate data transmission and minimizes errors in control or communication systems.

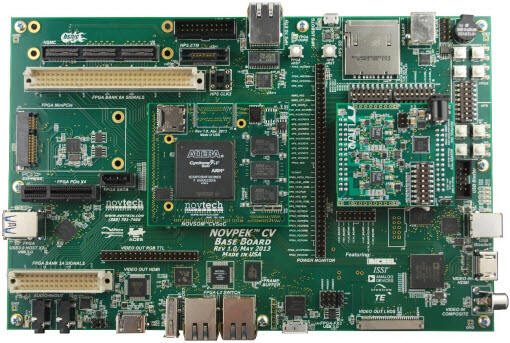

Modern PCBA combines surface mount and through-hole technologies to optimize performance and durability. Surface mount components allow for high-density layouts, while through-hole components provide mechanical strength for connectors and high-power devices. A well-balanced design ensures both electrical performance and mechanical reliability.

High-quality soldering is essential for PCBA reliability. Automated soldering processes such as reflow and wave soldering improve consistency. Additionally, post-solder inspection using X-ray, AOI (Automated Optical Inspection), or functional testing verifies assembly quality and identifies potential defects before deployment.

Before integrating PCBA into industrial systems, functional testing ensures that all circuits perform as intended under normal and stress conditions. This step verifies signal flow, power regulation, and control functionalities, reducing the likelihood of operational failures.

Industrial PCBA should undergo rigorous environmental testing, including temperature cycling, vibration testing, and humidity exposure. Stress testing validates that the assembly can withstand real-world operating conditions, ensuring reliability in critical applications.

Selecting an experienced PCBA supplier with industrial expertise is crucial. Reliable manufacturers maintain strict quality management systems, have proven process control, and provide traceability for components. Their expertise ensures consistent production of high-quality PCBA tailored to industrial requirements.

Reliable suppliers provide comprehensive documentation, including material certificates, assembly reports, and testing results. This transparency supports compliance audits and provides confidence that the PCBA meets the necessary industrial standards.

Industrial PCBA should be designed with serviceability in mind. Modular designs and accessible component layouts facilitate easier maintenance and reduce downtime during repairs. This approach ensures minimal disruption to industrial operations.

A reliable PCBA should use components with long-term availability to avoid obsolescence issues. Suppliers that offer lifecycle support and replacement parts ensure that the PCBA remains serviceable throughout the operational lifespan of industrial equipment.

While price is a consideration, the total cost of ownership includes reliability, maintenance frequency, and potential downtime costs. Investing in high-quality PCBA reduces long-term operational expenses and improves system stability.

Industrial PCBA selection involves balancing high-performance features such as advanced microcontrollers, robust connectivity, and thermal management with cost limitations. Choosing a PCBA that meets operational needs without excessive over-specification ensures optimal value.

Industrial PCBA increasingly incorporates IoT connectivity, enabling real-time monitoring, predictive maintenance, and data analytics. Selecting PCBA compatible with modern communication protocols ensures readiness for smart industrial environments.

Modern industrial applications often require edge computing capabilities. PCBA with sufficient processing power, memory, and connectivity supports local data processing, reducing latency and enhancing system responsiveness.

Reliability depends on quality components, robust thermal and electrical design, compliant manufacturing processes, and thorough testing under environmental stress.

Check certifications, review testing reports such as temperature cycling and vibration tests, and assess component ratings for temperature and humidity tolerance.

Durability should take priority, as industrial downtime is expensive. A well-designed PCBA balances performance, reliability, and reasonable cost.

Yes, selecting PCBA with compatible microcontrollers, communication modules, and modular design allows integration into IoT and automated systems.