inverter pcb price

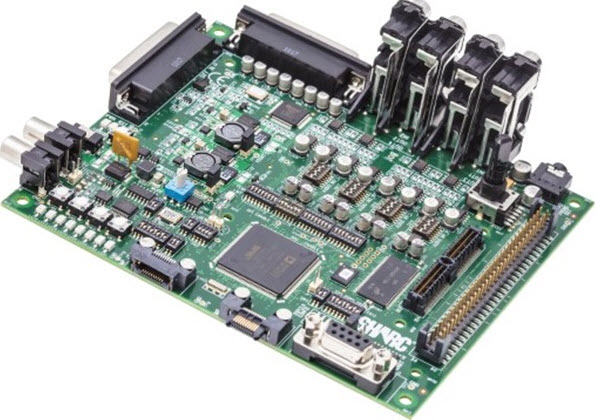

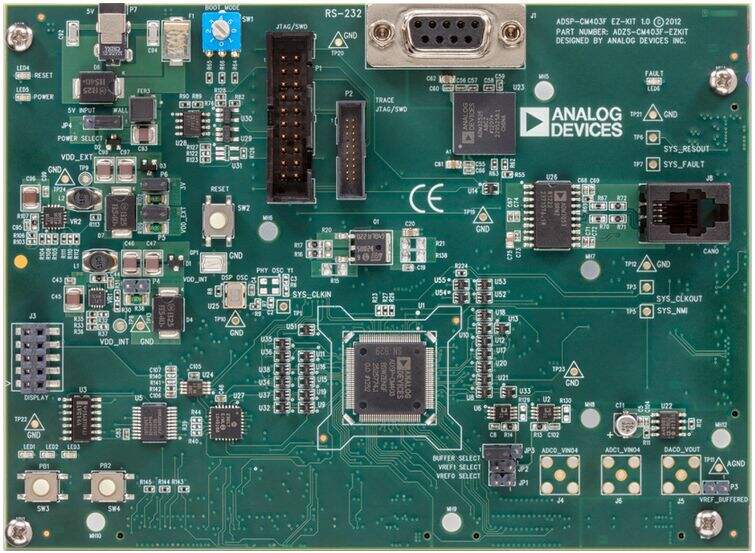

The inverter PCB price represents a crucial consideration in the power electronics industry, reflecting the complex manufacturing processes and components involved in creating these essential circuit boards. These specialized PCBs serve as the backbone of power conversion systems, enabling the transformation of DC to AC power through sophisticated electronic circuitry. The pricing structure typically varies based on several key factors, including board complexity, component quality, manufacturing volume, and technological specifications. Modern inverter PCBs incorporate advanced features such as multi-layer designs, thermal management systems, and high-frequency switching capabilities, all of which influence the final cost. The price point also accounts for the integration of protective elements like overcurrent protection, short circuit prevention, and EMI shielding. Market dynamics show that while basic inverter PCBs may start at more competitive price points, high-end versions with superior efficiency ratings and advanced control systems command premium prices. The cost consideration extends beyond the bare board to include factors such as component sourcing, assembly requirements, and quality testing procedures.