pcba service

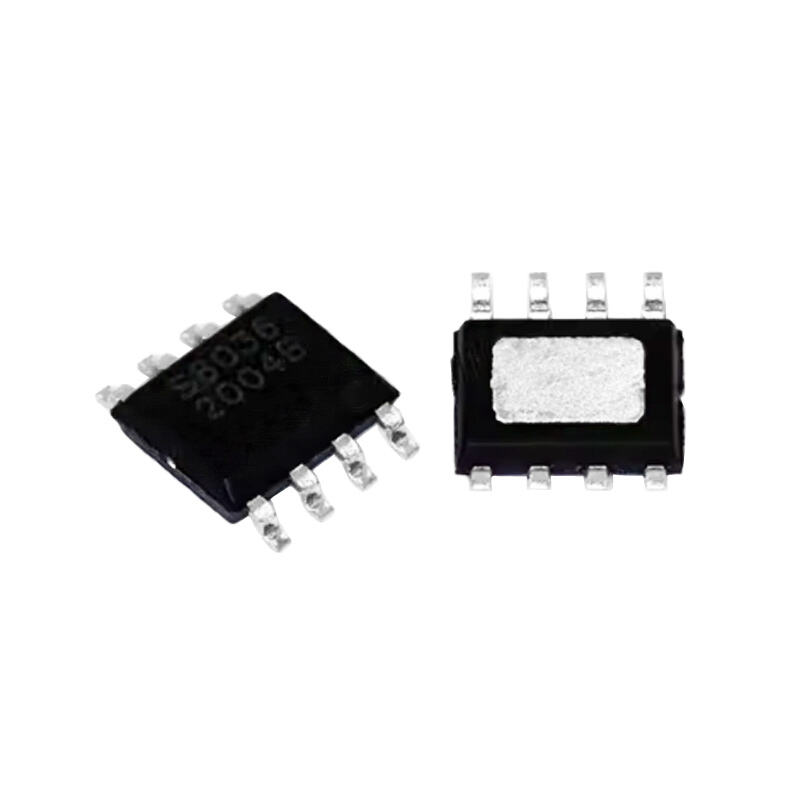

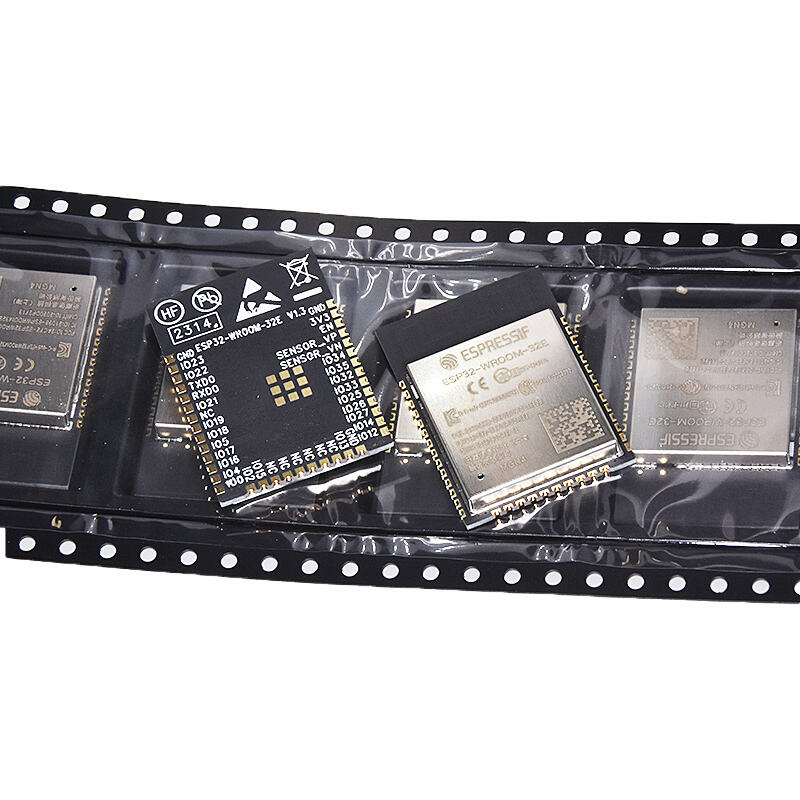

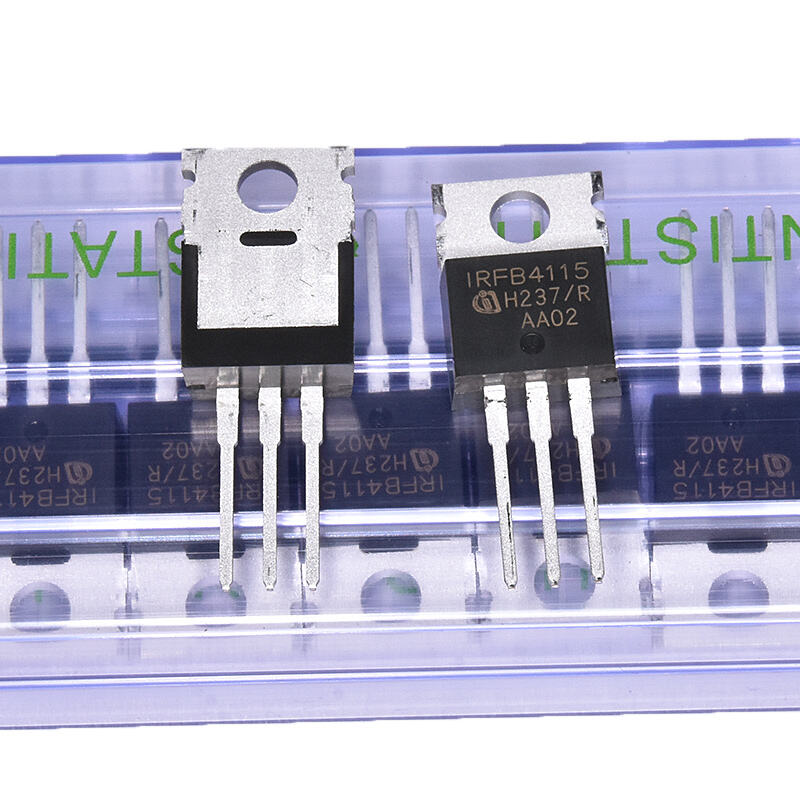

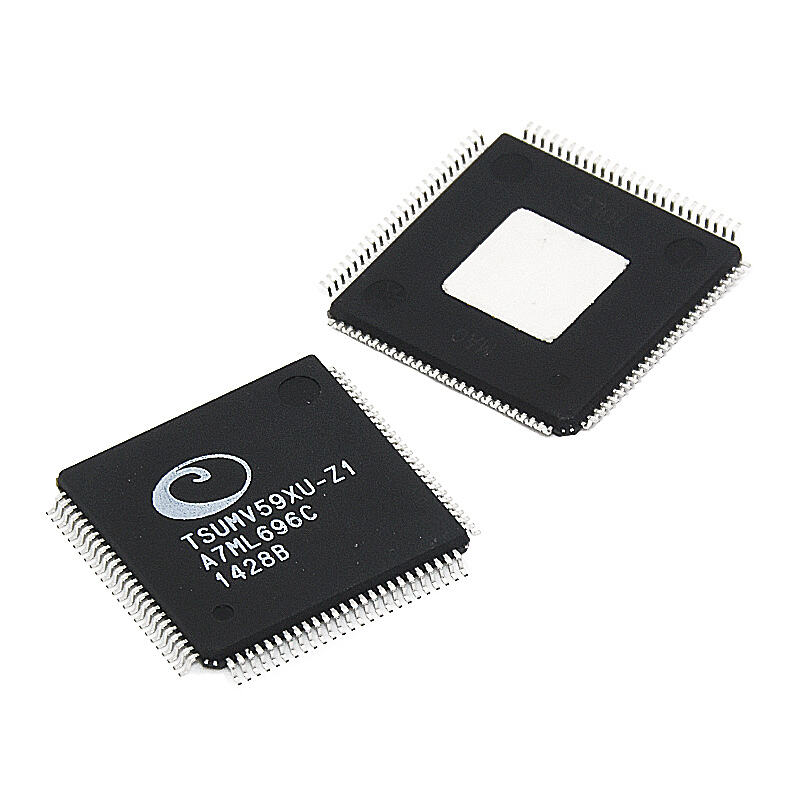

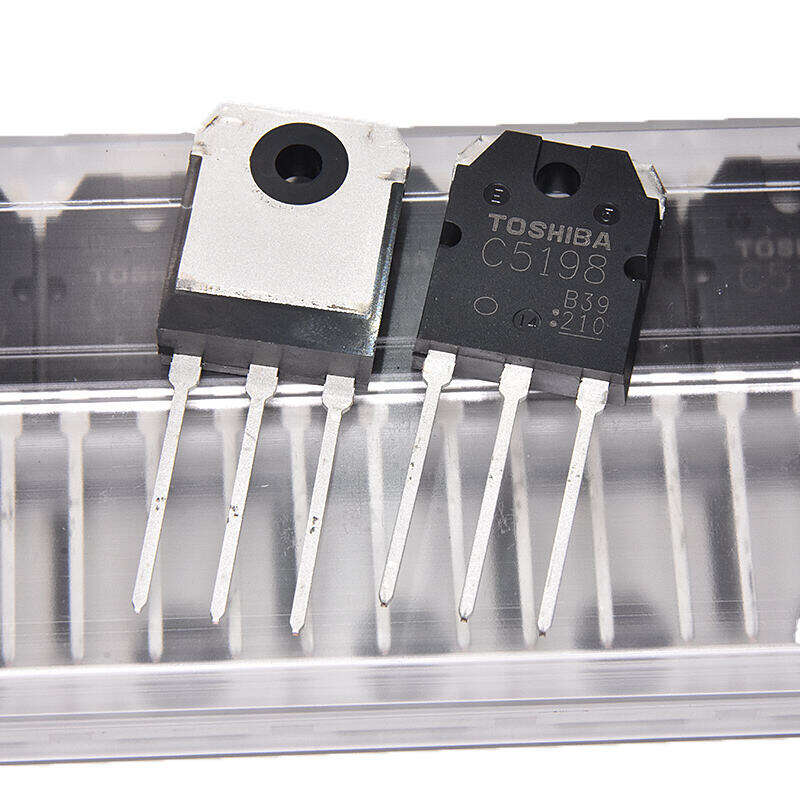

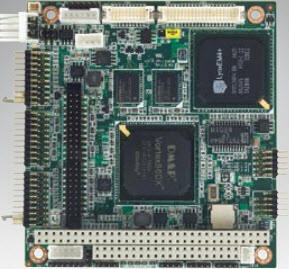

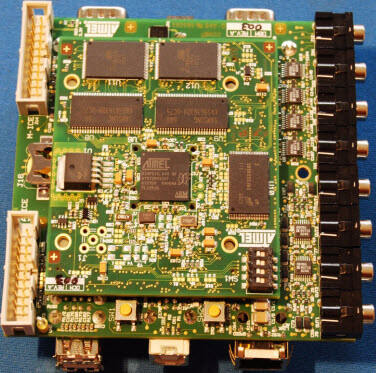

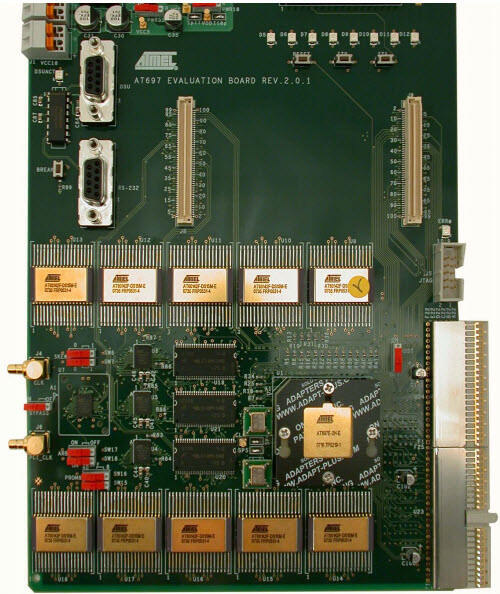

PCBA (Printed Circuit Board Assembly) service represents a comprehensive solution in electronics manufacturing, encompassing the complete process of populating printed circuit boards with electronic components. This sophisticated service combines cutting-edge technology with precision engineering to create fully functional electronic assemblies. The process begins with bare PCB procurement and extends through component placement, soldering, testing, and quality assurance. Modern PCBA services utilize advanced surface mount technology (SMT) and through-hole assembly techniques, supported by automated optical inspection (AOI) systems and X-ray inspection capabilities to ensure optimal quality. The service accommodates various production volumes, from prototype runs to high-volume manufacturing, while maintaining consistent quality standards. PCBA providers typically offer design for manufacturability (DFM) analysis, component sourcing, and supply chain management. These services are essential across multiple industries, including consumer electronics, automotive, medical devices, and industrial automation. The integration of Industry 4.0 principles enables real-time production monitoring and quality control, ensuring high yields and reliability in the final product.