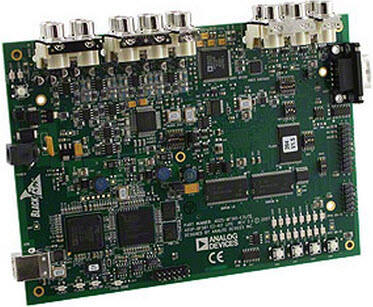

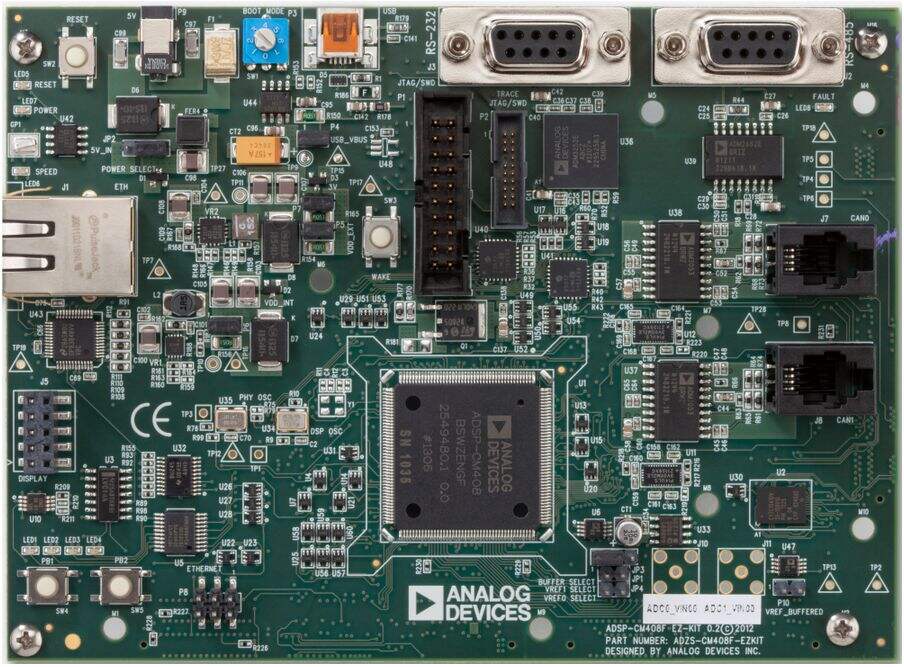

pCB de Alta Frecuencia

Los PCB de alta frecuencia (placas de circuito impreso) representan un avance sofisticado en la fabricación de circuitos electrónicos, diseñados específicamente para manejar señales que operan a frecuencias típicamente superiores a 1 GHz. Estas placas especializadas están diseñadas con control preciso de impedancia, mínima pérdida de señal y una compatibilidad electromagnética superior. Su construcción utiliza materiales cuidadosamente seleccionados con constantes dieléctricas y tangentes de pérdida específicas, como sustratos basados en Rogers, Taconic o PTFE, que mantienen la integridad de la señal a altas frecuencias. El diseño incorpora técnicas específicas de disposición, incluyendo anchos de traza controlados, espaciado preciso y optimización del plano de tierra para gestionar la interferencia electromagnética y mantener la calidad de la señal. Los PCB de alta frecuencia son esenciales en equipos modernos de telecomunicaciones, sistemas de radar, comunicaciones por satélite y dispositivos digitales de alta velocidad. Cuentan con tratamientos especiales de láminas de cobre, controles precisos de espesor y acabados superficiales avanzados para garantizar un rendimiento óptimo. El proceso de fabricación exige una extrema precisión en perforación, grabado y laminación para mantener las características eléctricas críticas requeridas en aplicaciones de alta frecuencia. Estas placas suelen incluir elementos adicionales de diseño, como líneas de transmisión stripline, microstrip y vías cuidadosamente calculadas, para mantener la integridad de la señal a lo largo de todo el recorrido del circuito.