costo de ensamblaje de pcb

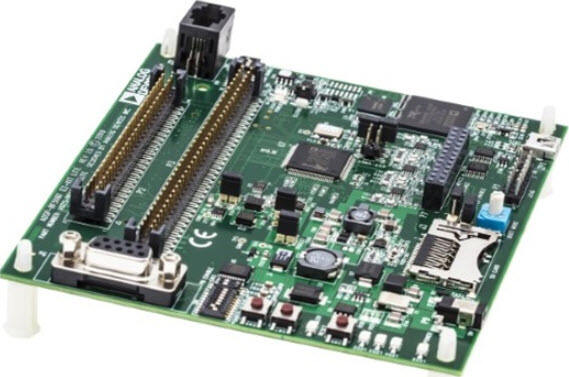

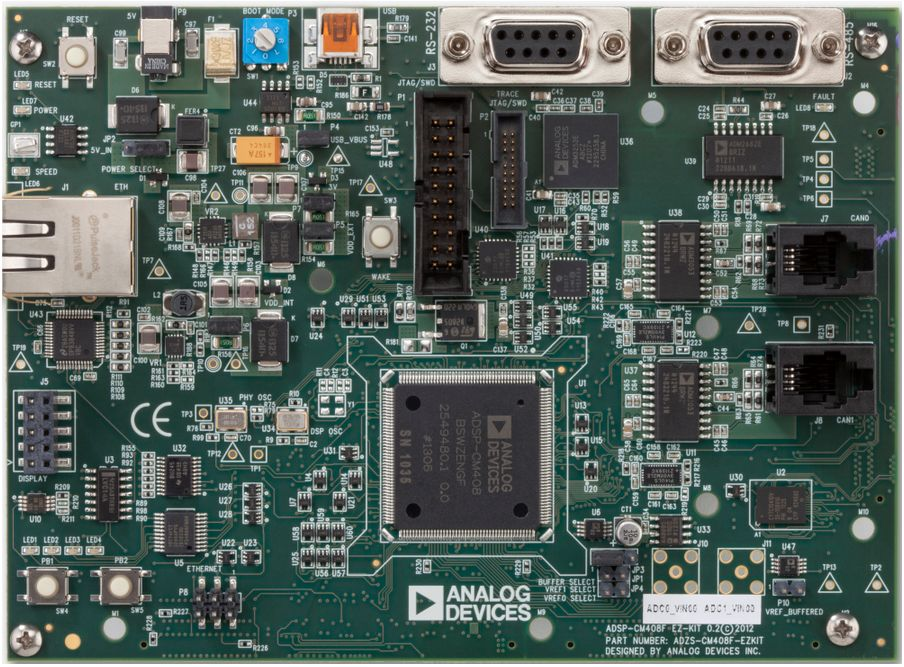

El costo de ensamblaje de PCB representa un factor crucial en la fabricación electrónica, que comprende diversos elementos que contribuyen al gasto final de la producción de placas de circuito impreso. Esta estructura de costos integral incluye materiales, mano de obra, uso de equipos y gastos generales. El proceso de ensamblaje implica la colocación de componentes, soldadura, pruebas y medidas de control de calidad, cada uno de los cuales aumenta el costo total. Las instalaciones modernas de ensamblaje de PCB utilizan tecnologías avanzadas de montaje superficial (SMT) y tecnología de orificio pasante (THT) para lograr una colocación precisa de componentes y conexiones confiables. El costo varía significativamente según factores como la complejidad de la placa, los tipos de componentes, el volumen de producción y los requisitos de calidad. Los fabricantes suelen emplear diferentes modelos de precios, incluyendo precios por componente, cálculos basados en el tiempo de ensamblaje o cotizaciones por proyecto. La implementación de líneas de ensamblaje automatizadas ha ayudado a reducir costos manteniendo altos estándares de calidad. Además, factores como el tamaño de la placa, el número de capas, la densidad de componentes y requisitos especiales como recubrimiento conformal o protocolos de prueba influyen en el costo final del ensamblaje. Comprender estos componentes de costo es esencial tanto para fabricantes como para clientes para optimizar sus estrategias de producción y mantener precios competitivos en el mercado.