pcba oem

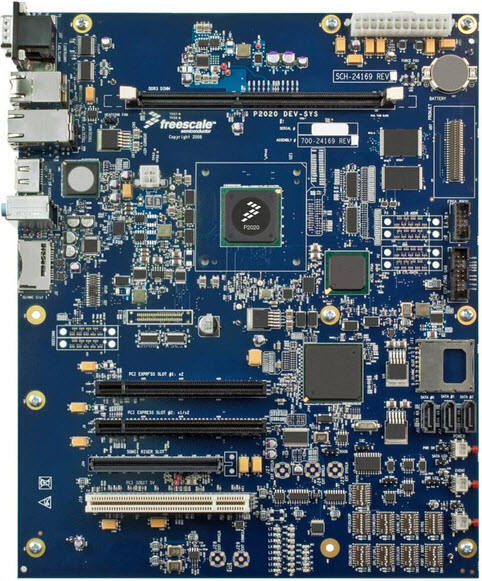

PCBA OEM (Manufacturación de Equipos Originales de Ensamblaje de Circuitos Impresos) representa un servicio integral que abarca todo el proceso de fabricación de placas de circuitos electrónicos. Esta sofisticada solución de fabricación combina tecnología avanzada con ingeniería de precisión para producir ensamblajes electrónicos de alta calidad. El proceso incluye la fabricación de PCB, adquisición de componentes, ensamblaje mediante tecnología de montaje superficial (SMT), ensamblaje por orificio pasante y pruebas de calidad. Los servicios de PCBA OEM utilizan equipos de última generación y líneas de producción automatizadas para garantizar una calidad constante y una alta eficiencia. Estas instalaciones están equipadas con máquinas avanzadas de colocación SMT, hornos de reflujo, sistemas de inspección óptica automática (AOI) y equipos completos de pruebas. El servicio abarca diversas industrias, desde electrónica de consumo hasta automotriz, dispositivos médicos y equipos industriales. Los proveedores de servicios PCBA OEM ofrecen flexibilidad en volúmenes de producción, desde prototipos hasta fabricación de alto volumen, manteniendo al mismo tiempo rigurosos estándares de control de calidad durante todo el proceso. También ofrecen servicios adicionales como análisis de diseño para facilitar la fabricación (DFM), ingeniería de componentes y gestión de la cadena de suministro, asegurando resultados óptimos de producción y rentabilidad.