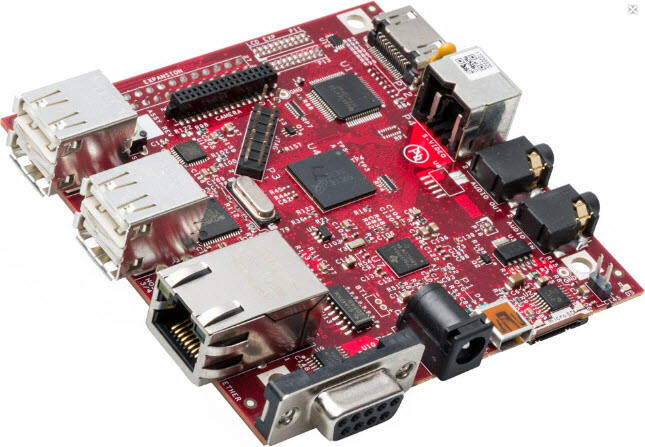

dispositivo pcba

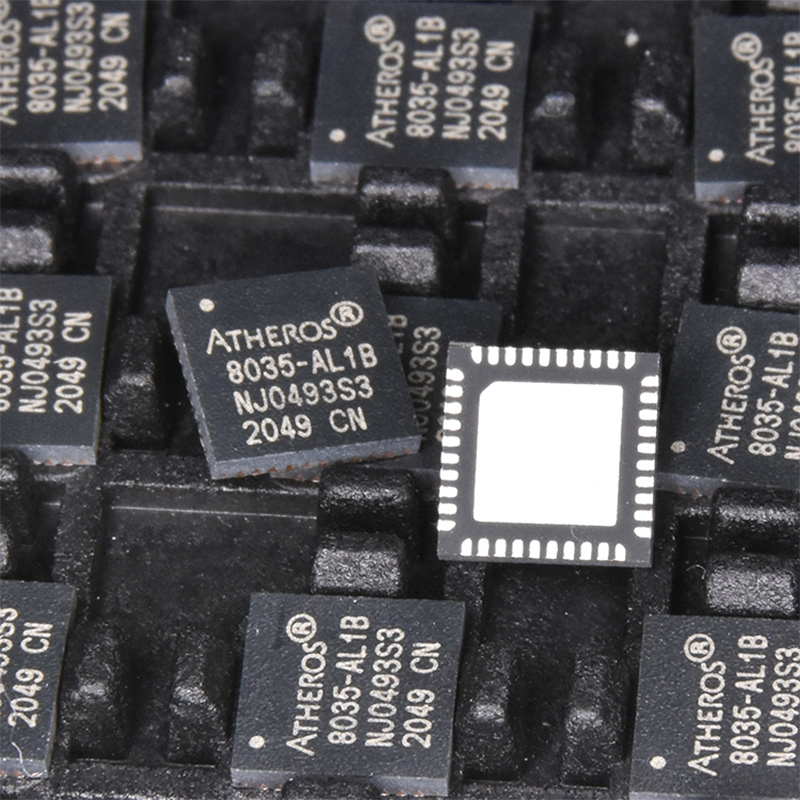

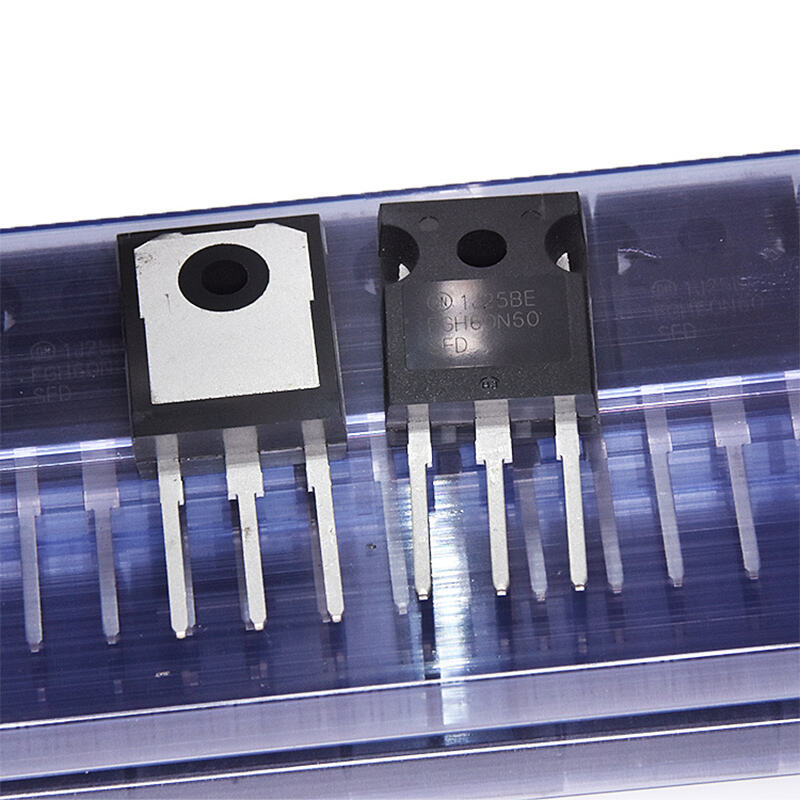

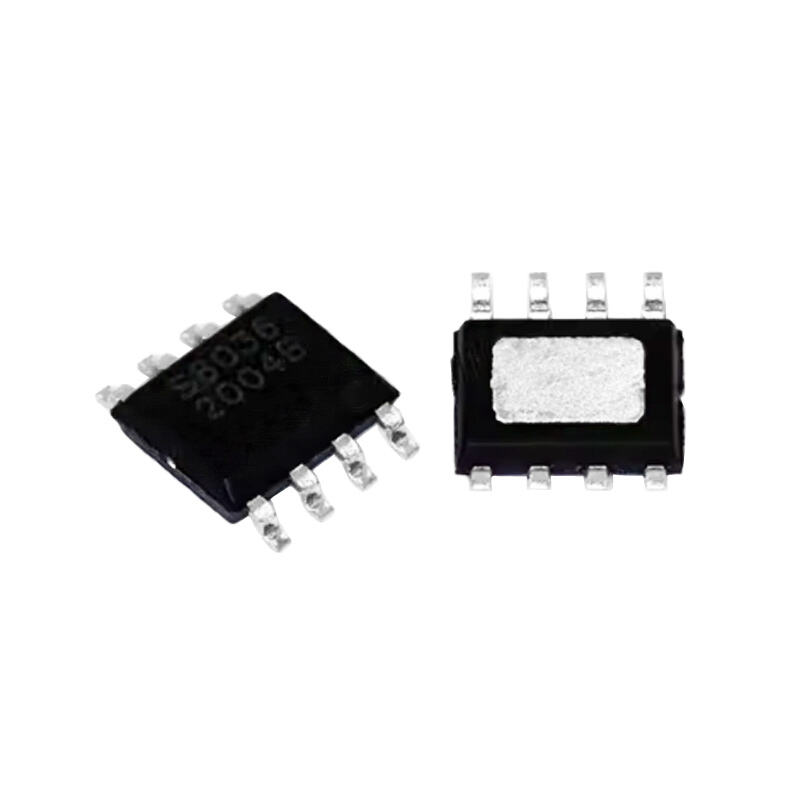

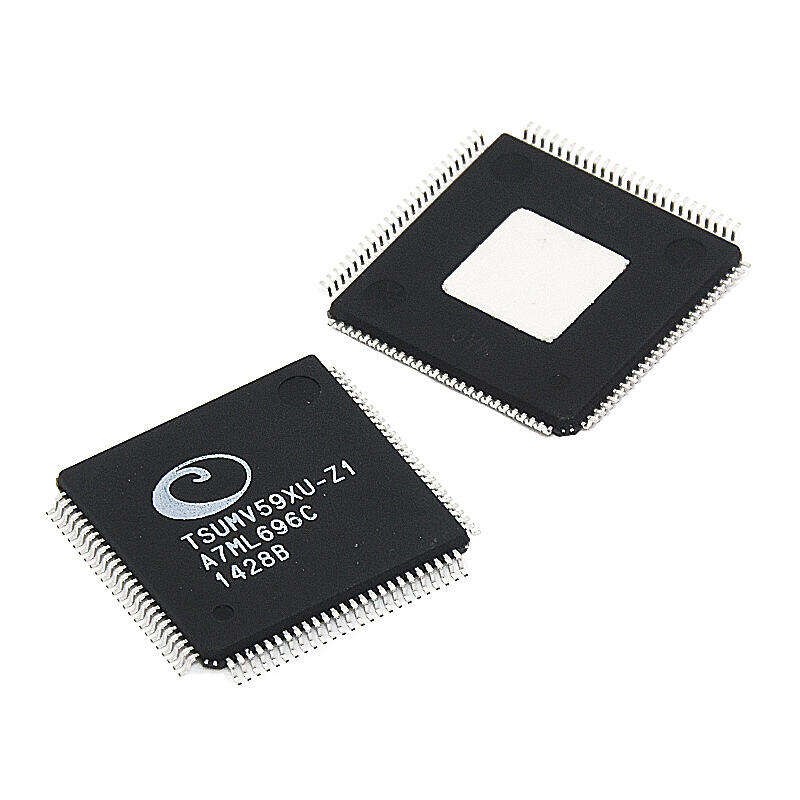

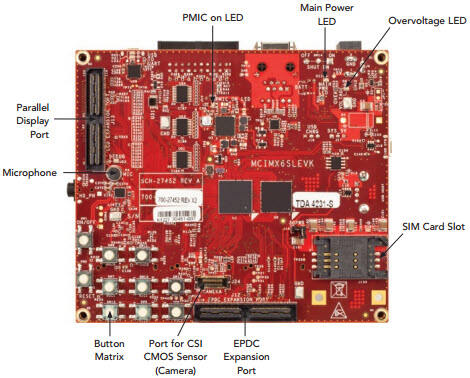

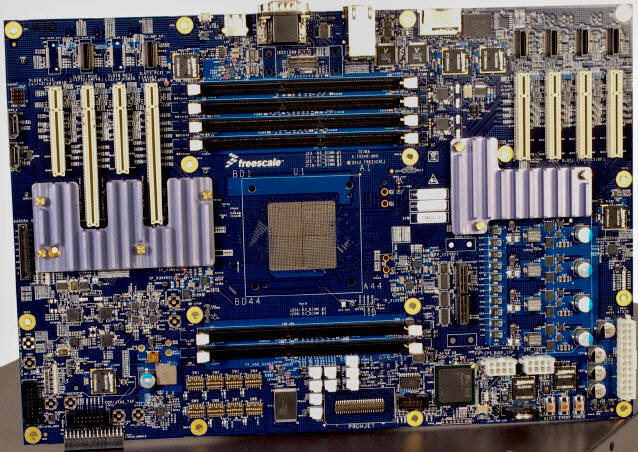

Un dispositivo PCBA (ensamblaje de placa de circuito impreso) representa la piedra angular de la fabricación electrónica moderna, actuando como la placa de circuito funcional completa que alimenta innumerables dispositivos electrónicos. Este componente sofisticado combina una PCB básica con diversas partes electrónicas, incluyendo circuitos integrados, resistencias, capacitores y conectores, todos soldados con precisión para crear un ensamblaje electrónico totalmente operativo. El proceso de fabricación implica tecnologías avanzadas de montaje en superficie (SMT) y técnicas de montaje pasante, asegurando conexiones eléctricas confiables y un rendimiento óptimo. Los PCBA funcionan como el cerebro de los dispositivos electrónicos, procesando señales, gestionando la distribución de energía y coordinando varios componentes para realizar tareas específicas. Estos dispositivos versátiles se encuentran en todo tipo de equipos, desde teléfonos inteligentes y computadoras portátiles hasta equipos de automatización industrial y dispositivos médicos. Su diseño incorpora múltiples capas de circuitos, permitiendo una funcionalidad compleja manteniendo al mismo tiempo un factor de forma compacto. Los dispositivos PCBA modernos suelen incluir protocolos de pruebas automatizadas, medidas de control de calidad y recubrimientos de protección ambiental para garantizar durabilidad y fiabilidad en diversas condiciones de funcionamiento.