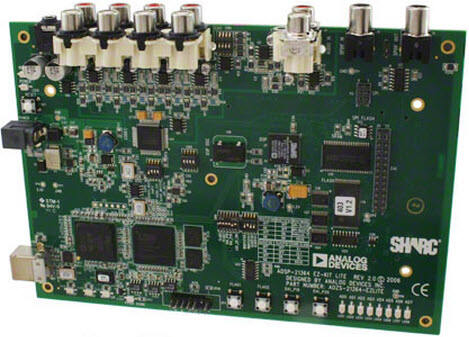

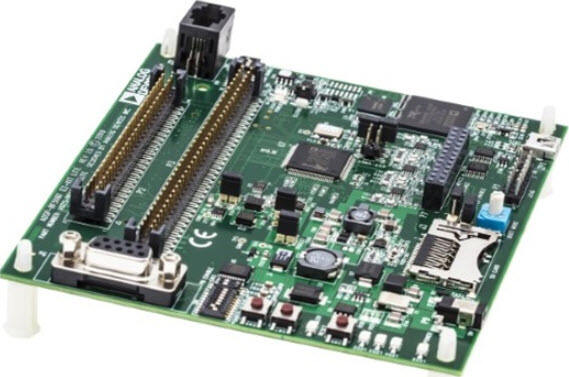

pcb vert

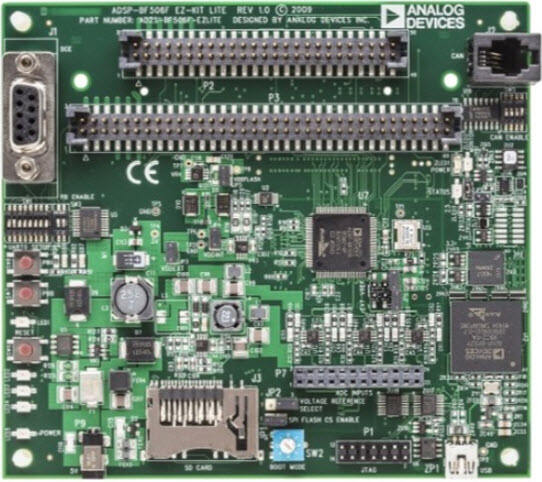

Un PCB vert (circuit imprimé) représente un composant fondamental dans la fabrication électronique moderne, caractérisé par son revêtement distinctif de masque de soudure vert. Ce circuit spécialisé sert de base pour relier les composants électroniques via des pistes conductrices, généralement en cuivre. La coloration verte n'est pas uniquement esthétique, mais remplit des fonctions essentielles. Le masque de soudure, qui donne au circuit imprimé son apparence verte caractéristique, assure une protection cruciale contre l'oxydation et les courts-circuits tout en facilitant le soudage correct des composants. Ces cartes sont fabriquées à partir de matériau FR-4, un stratifié ignifuge en époxy renforcé de fibres de verre offrant d'excellentes propriétés d'isolation électrique et une grande résistance mécanique. Les circuits imprimés verts sont largement utilisés dans divers secteurs, allant de l'électronique grand public aux systèmes d'automatisation industrielle. Ils intègrent des pistes en cuivre conçues avec précision afin d'assurer des connexions électriques fiables entre les composants, tandis que le masque de soudure vert garantit une visibilité optimale lors des inspections et des contrôles qualité. Ces cartes peuvent être produites en plusieurs couches, permettant des conceptions de circuits complexes dans un facteur de forme compact. Leur processus de fabrication standardisé assure cohérence et fiabilité, ce qui les rend idéaux tant pour le développement de prototypes que pour la production de masse.