service de prototype de carte pcb

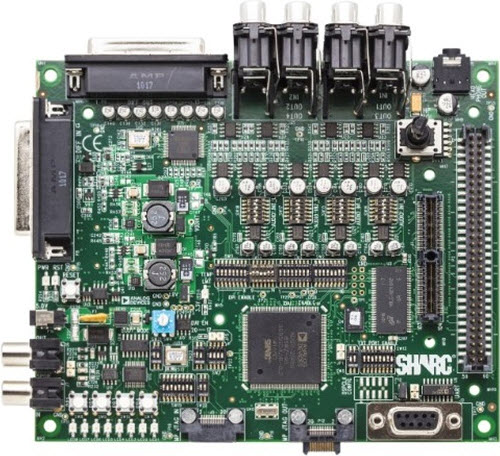

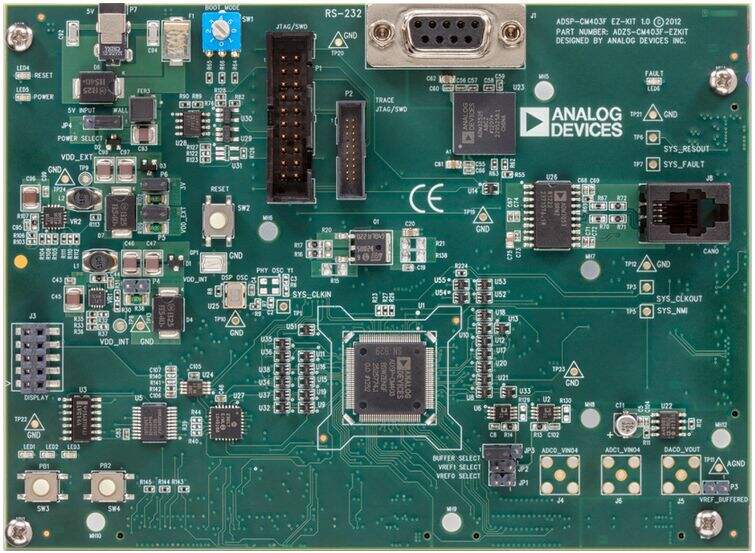

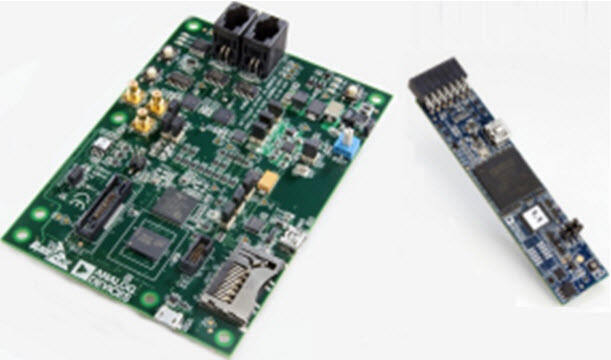

Le service de prototype de PCB représente une étape cruciale dans le développement de produits électroniques, offrant une fabrication rapide et précise d'échantillons de circuits imprimés avant la production à grande échelle. Ce service complet comprend la vérification des conceptions, le choix des matériaux et des processus de fabrication adaptés aux exigences spécifiques de chaque projet. Le service utilise des systèmes avancés de CAO/FAO et des équipements de fabrication automatisés pour garantir une haute précision et une grande cohérence dans la création des prototypes. Les services modernes de prototypes de PCB intègrent des technologies de pointe telles que l'inspection optique automatisée (AOI), les tests par palpeur volant et l'inspection par rayons X afin d'assurer qualité et fonctionnalité. Ces services peuvent gérer divers niveaux de complexité de cartes, allant des conceptions monocouches à multicouches, et s'adaptent à différents matériaux et spécifications de cartes. Le délai de livraison varie généralement entre 24 heures et plusieurs jours, selon la complexité et les exigences. Le service inclut des mesures complètes de contrôle qualité, des vérifications des règles de conception (DRC) et des tests électriques pour s'assurer que les prototypes répondent à toutes les spécifications. En outre, de nombreux prestataires proposent des services complémentaires tels que l'approvisionnement en composants, des services d'assemblage et des consultations techniques pour accompagner l'ensemble du processus de prototypage.