progettazione e produzione di PCB

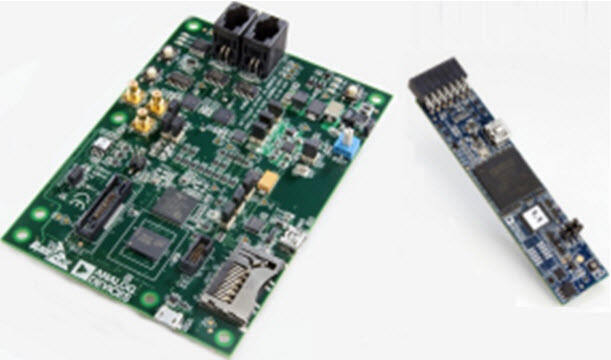

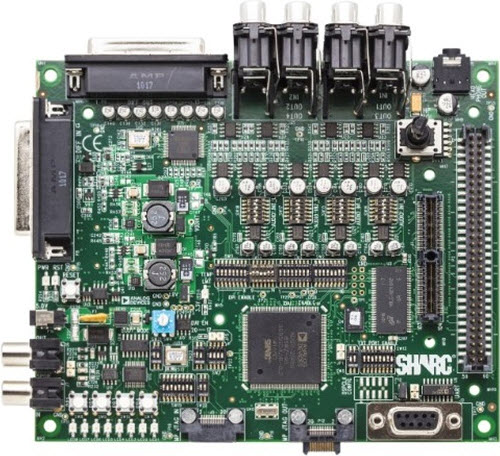

La progettazione e produzione di PCB rappresenta un processo cruciale nella moderna produzione di dispositivi elettronici, comprendendo la creazione e la fabbricazione di schede a circuito stampato che costituiscono la base dei dispositivi elettronici. Questo processo sofisticato inizia con la progettazione concettuale mediante software CAD avanzati, in cui gli ingegneri pianificano meticolosamente la disposizione dei componenti elettronici e dei percorsi conduttivi. La fase di produzione comprende diverse fasi, tra cui la preparazione del substrato, la laminazione del rame, l'applicazione del fotoresist, la morsura chimica (etching) e la finitura superficiale. I moderni impianti di progettazione e produzione di PCB utilizzano attrezzature all'avanguardia per il posizionamento preciso dei componenti, test automatizzati e misure di controllo qualità. Il processo supporta diversi tipi di schede, da quelle monolivello a progetti multilivello complessi, adatti ad applicazioni che vanno dall'elettronica di consumo alla tecnologia aerospaziale. Le caratteristiche avanzate includono il controllo dell'impedenza, soluzioni per la gestione termica e capacità di interconnessione ad alta densità (HDI). Il settore evolve continuamente per soddisfare requisiti sempre più stringenti in termini di miniaturizzazione, prestazioni elevate e maggiore affidabilità. Gli impianti produttivi rispettano rigorosamente gli standard internazionali offrendo al contempo opzioni di personalizzazione per esigenze specifiche di progetto.