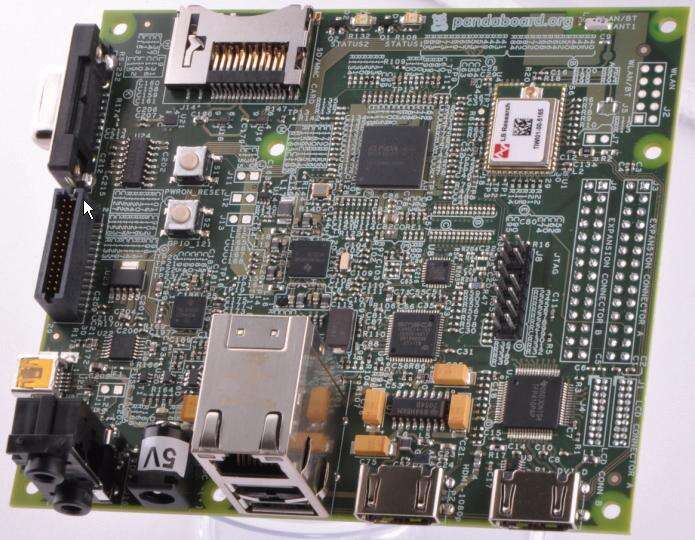

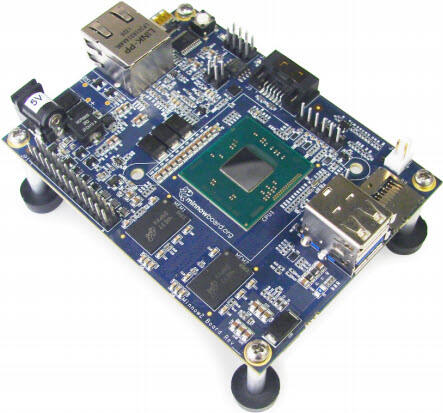

대량 PCBA

대량 PCBA(Printed Circuit Board Assembly)는 전자제품 생산에서 효율성과 정밀성을 결합한 포괄적인 제조 솔루션을 의미합니다. 이 공정은 전자 부품을 인쇄회로기판에 대량으로 조립하여 규모 있는 기능성 전자 장치를 제작하는 과정을 포함합니다. 본 기술은 첨단 표면실장기술(SMT)과 스루홀 조립 방식을 활용하여 동일한 회로기판 여러 개를 동시에 생산할 수 있습니다. 각각의 PCBA는 자동광학검사(AOI)와 기능 테스트를 포함한 엄격한 품질 관리 절차를 거쳐 대규모 생산에서도 일관된 성능을 보장합니다. 이 공정은 기본 저항기 및 커패시터부터 복잡한 집적회로(IC) 및 마이크로프로세서까지 다양한 종류의 부품을 처리할 수 있습니다. 대량 PCBA 제조는 소비자 가전, 자동차 시스템, 산업용 자동화 등 대량의 전자 부품 생산이 요구되는 산업 분야에서 특히 중요합니다. 이 공정은 현대적인 제조 기술과 정교한 품질 보증 프로토콜을 통합하여 다양한 응용 분야에 신뢰성 높고 비용 효율적인 전자 조립품을 제공합니다.