pCBA 조달

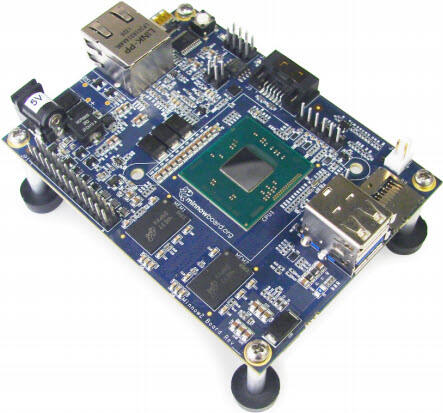

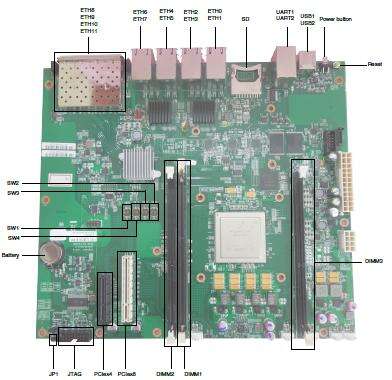

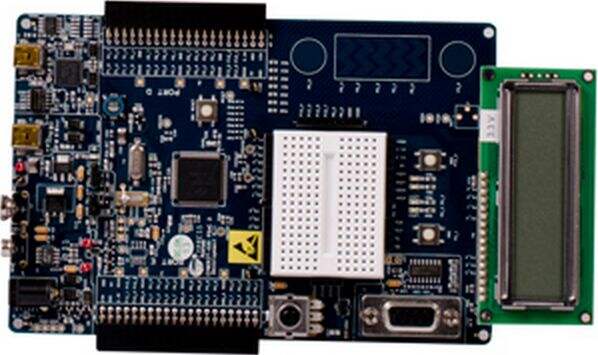

PCBA 조달은 부품 선정부터 최종 품질 보증에 이르기까지 인쇄회로기판 어셈블리(PCBA)를 조달하는 포괄적인 과정을 의미합니다. 이 전략적 접근 방식은 특정 기술 사양과 비용 목표를 충족하면서 고품질 PCBA를 제공할 수 있는 신뢰할 수 있는 제조업체를 파악하고 협력하는 것을 포함합니다. 이 과정에는 철저한 공급업체 평가, 부품 조달 관리, 품질 관리 실행 및 공급망 최적화가 포함됩니다. 현대의 PCBA 조달은 생산 상태, 품질 지표, 재고 수준에 대한 실시간 모니터링을 가능하게 하는 첨단 기술 플랫폼을 활용합니다. 이러한 시스템은 엔터프라이즈 자원 계획(ERP) 솔루션과 원활하게 통합되어 다양한 이해관계자 간 효율적인 협업을 지원합니다. 또한 PCBA 조달에는 신뢰성을 보장하기 위한 철저한 테스트 절차인 자동 광학 검사(AOI), 인서킷 테스트(ICT), 기능 테스트 등이 포함됩니다. 더불어 많은 공급업체들이 이제 친환경 제조 옵션과 RoHS 규격 부품을 제공함에 따라, PCBA 조달은 지속 가능성 요소도 고려하고 있습니다. 이러한 포괄적인 접근 방식을 통해 조직은 규모의 경제와 전략적 공급업체 관계를 통해 비용을 최적화하면서 일관된 품질을 유지할 수 있습니다.