โรงงานผลิตแผงวงจรพีซีบีเอ

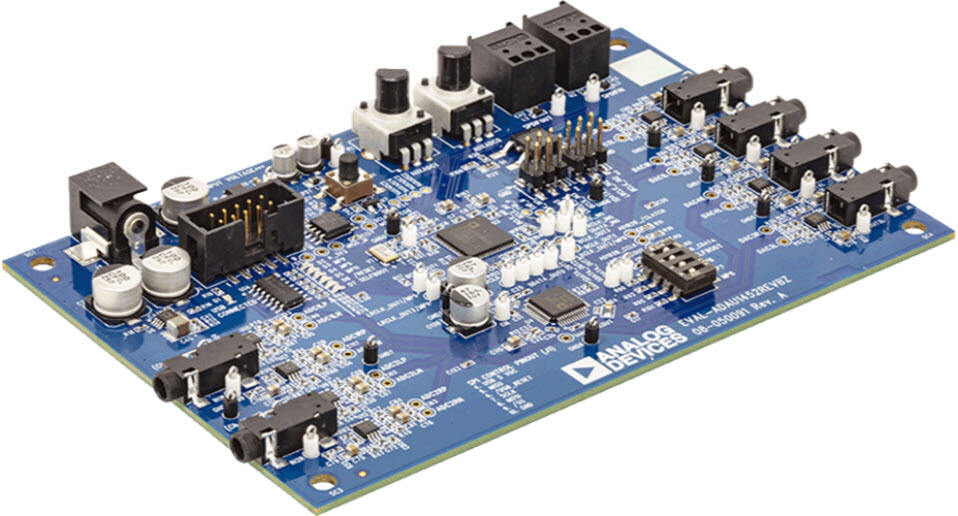

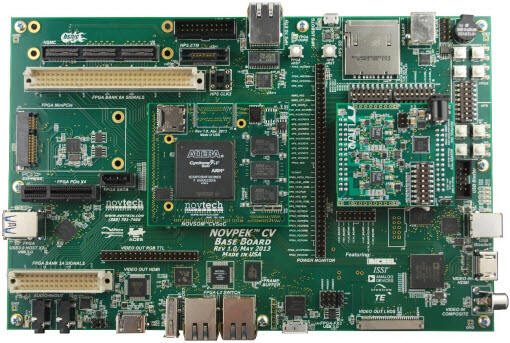

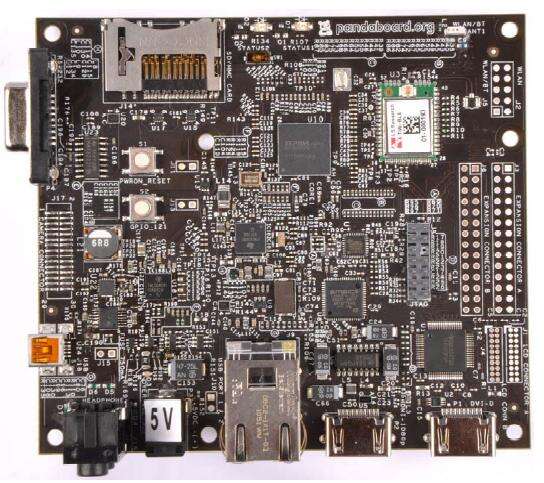

โรงงานประกอบแผงวงจรพีซีบีเอ (PCBA) เป็นสถานที่ผลิตขั้นสูงที่เชี่ยวชาญในการประกอบแผ่นวงจรพิมพ์ สถานที่เหล่านี้รวมเทคโนโลยีการผลิตอัตโนมัติขั้นสูงกับวิศวกรรมความแม่นยำ เพื่อผลิตชิ้นส่วนอิเล็กทรอนิกส์คุณภาพสูง โรงงานดังกล่าวประกอบด้วยโซนเฉพาะทางหลายแห่ง ได้แก่ สายการผลิต SMT (Surface Mount Technology), พื้นที่ประกอบแบบผ่านรู, สถานีทดสอบ และแผนกควบคุมคุณภาพ โรงงาน PCBA สมัยใหม่ใช้อุปกรณ์ขั้นสูง เช่น เครื่องจักรวางชิ้นส่วนอัตโนมัติ (pick-and-place machines), เตาอบรีฟโลว์ (reflow ovens), และระบบตรวจสอบด้วยภาพอัตโนมัติ (automated optical inspection systems) เพื่อให้มั่นใจในคุณภาพของผลิตภัณฑ์อย่างต่อเนื่อง ความสามารถของโรงงานมักครอบคลุมตั้งแต่การพัฒนาต้นแบบไปจนถึงการผลิตจำนวนมาก เพื่อรองรับอุตสาหกรรมต่างๆ เช่น อุตสาหกรรมยานยนต์ การสื่อสารโทรคมนาคม อุปกรณ์อิเล็กทรอนิกส์สำหรับผู้บริโภค และอุปกรณ์ทางการแพทย์ การควบคุมสภาพแวดล้อมจะรักษาระดับอุณหภูมิ ความชื้น และความสะอาดให้อยู่ในเกณฑ์เหมาะสม เพื่อป้องกันไฟฟ้าสถิตและการปนเปื้อน กระบวนการผลิตภายในโรงงานถูกจัดการโดยระบบการดำเนินงานการผลิตขั้นสูง (manufacturing execution systems) ที่สามารถตรวจสอบแบบเรียลไทม์ ติดตามย้อนกลับได้ และรับประกันคุณภาพตลอดกระบวนการผลิต ด้วยการผสานรวมเข้ากับระบบ Industry 4.0 สถานที่ผลิตเหล่านี้จึงสามารถให้ข้อมูลเชิงลึกจากข้อมูล การบำรุงรักษาเชิงคาดการณ์ (predictive maintenance) และระบบอัตโนมัติอัจฉริยะ เพื่อเพิ่มประสิทธิภาพการผลิตและลดต้นทุน