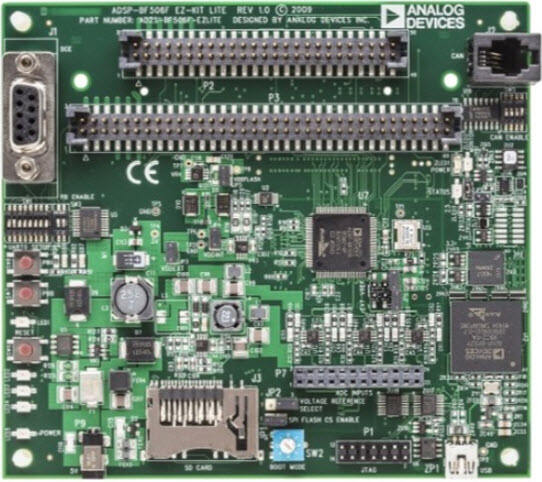

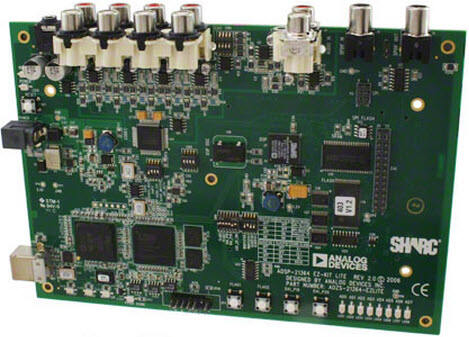

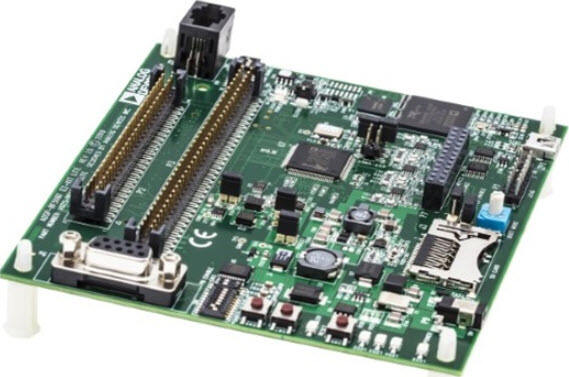

yeşil pcb

Yeşil bir PCB (Baskı Devre Kartı), karakteristik yeşil lehim maskesi kaplamasıyla dikkat çeken, modern elektronik üretimde temel bir bileşendir. Bu özel kart, genellikle bakırдан yapılan iletken yollar aracılığıyla elektronik bileşenleri birbirine bağlamak için temel oluşturur. Yeşil renk yalnızca estetik değil, aynı zamanda önemli işlevsel amaçlar taşır. PCB'nin karakteristik yeşil görünümünü veren lehim maskesi, oksidasyona ve kısa devrelere karşı gerekli korumayı sağlarken bileşenlerin uygun şekilde lehimlenmesini de kolaylaştırır. Bu kartlar, mükemmel elektrik yalıtım özellikleri ve mekanik dayanıklılık sunan alev geciktirici cam elyaf takviyeli epoksi laminattan oluşan FR-4 malzemesi kullanılarak üretilir. Yeşil PCB'ler tüketici elektroniğinden endüstriyel otomasyon sistemlerine kadar çeşitli sektörlerde yaygın olarak kullanılır. Bileşenler arasında güvenilir elektrik bağlantıları oluşturan hassas mühendislikle tasarlanmış bakır izlere sahiptir ve yeşil lehim maskesi muayene ile kalite kontrol süreçleri için optimal görünürlük sağlar. Bu kartlar, kompakt bir formda karmaşık devre tasarımlarına olanak tanıyan çok katmanlı olarak üretilebilir. Standartlaştırılmış üretim süreci, tutarlılık ve güvenilirliği garanti eder ve hem prototip geliştirme hem de seri üretim uygulamaları için ideal hale getirir.