pcb tedarikçileri

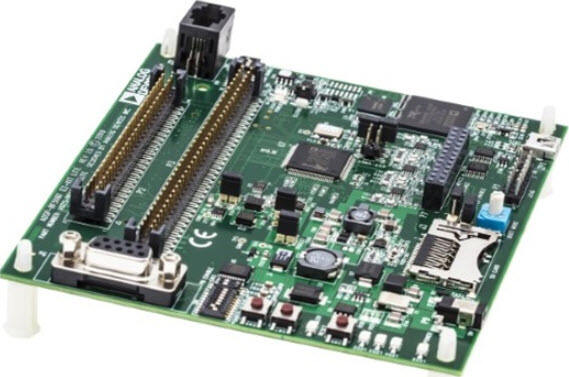

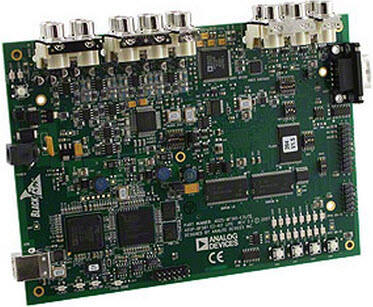

PCB tedarikçileri, modern elektronik cihazlar için gerekli olan yüksek kaliteli baskılı devre kartlarını sağlayarak elektronik üretim sektöründe kritik bir rol oynar. Bu tedarikçiler, çeşitli spesifikasyonlara ve endüstri standartlarına uygun PCB'ler üretmek için gelişmiş üretim teknolojilerini ve kalite kontrol süreçlerini kullanır. Otomotiv, telekomünikasyon, tıbbi cihazlar ve tüketici elektroniği gibi çeşitli sektörleri kapsayacak şekilde prototip geliştirme ile seri üretime kadar kapsamlı hizmetler sunarlar. Modern PCB tedarikçileri, otomatik optik muayene sistemleri, flying probe test cihazları ve gelişmiş delme makineleri gibi hassas üretim için sofistike ekipmanlar kullanır. Tek katmanlı, çok katmanlı, sert, esnek ve sert-esnek panolar da dahil olmak üzere farklı teknik gereksinimleri ve uygulamaları karşılayabilecek birçok PCB türü sağlarlar. Ayrıca, optimum üretim sonuçlarını sağlamak için tasarım incelemesi, DFM (Üretilebilirlik için Tasarım) analizi ve teknik danışmanlık gibi değer artırıcı hizmetler de sunarlar. Kaplama malzemeleri, yüzey kaplamaları, empedans kontrolü ve yüksek frekanslı uygulamalar gibi özel gereksinimler başta olmak üzere çeşitli kart malzemelerini işleme konusunda da yetkinlikleri vardır.