خدمات تخطيط لوحة الدوائر المطبوعة

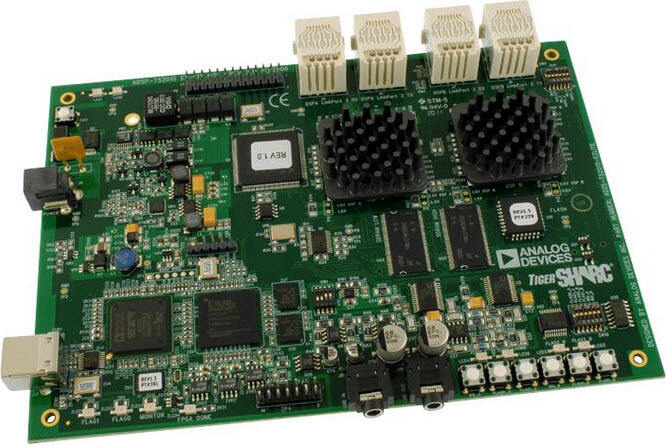

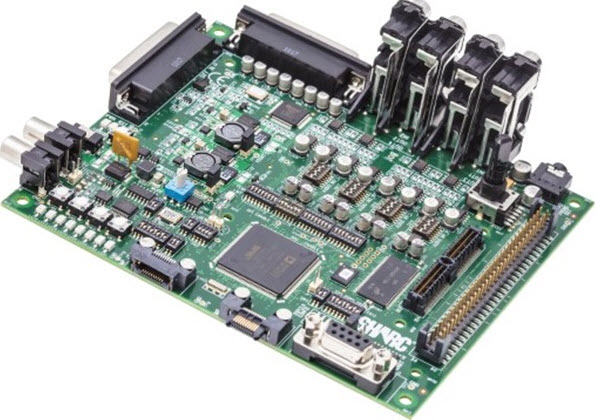

تمثل خدمات تخطيط اللوحات المطبوعة (PCB) مرحلة حاسمة في تطوير المنتجات الإلكترونية، وتشمل العملية المعقدة لتصميم وتوزيع المكونات الإلكترونية ووصلاتها على لوحة الدوائر المطبوعة. وتستخدم هذه الخدمات الاحترافية برامج تصميم بمساعدة الحاسوب (CAD) المتطورة لإنشاء تخطيطات دقيقة وقابلة للتصنيع، بحيث يتم تحسين الأداء واستغلال المساحة في آنٍ واحد. وعادةً ما تبدأ الخدمة بالتقاط المخطط التخطيطي (Schematic Capture)، ثم تتبعه عملية وضع المكونات، وتمديد التوصيلات الكهربائية، وتطبيق قواعد التصميم. وتشمل خدمات تخطيط اللوحات الحديثة ميزات متقدمة مثل التصاميم متعددة الطبقات، والتحكم في المعاوقة، وتمديد الإشارات عالية السرعة، واعتبارات إدارة الحرارة. وتعتبر هذه الخدمات ضرورية عبر مختلف الصناعات، بما في ذلك الاتصالات، والإلكترونيات في صناعة السيارات، والأجهزة الطبية، والإلكترونيات الاستهلاكية. ويضمن الخبراء المختصون الامتثال للمعايير الصناعية ومتطلبات التصنيع، مع معالجة مسائل التوافق الكهرومغناطيسي، وسلامة الإشارة، والاعتبارات الحرارية. كما تشمل خدمات تخطيط اللوحات الاحترافية إعداد وثائق شاملة، والتحقق من قواعد التصميم، وتوليد ملفات التصنيع، مما يضمن انتقالًا سلسًا من التصميم إلى الإنتاج.