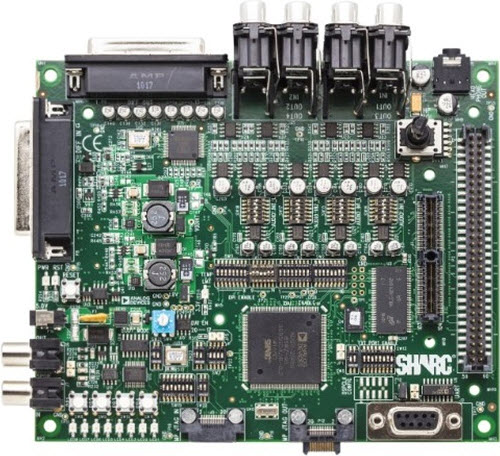

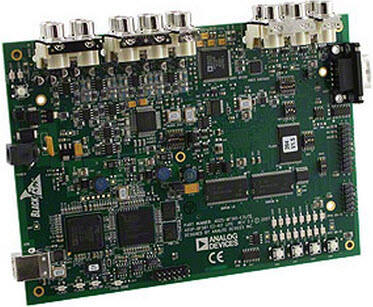

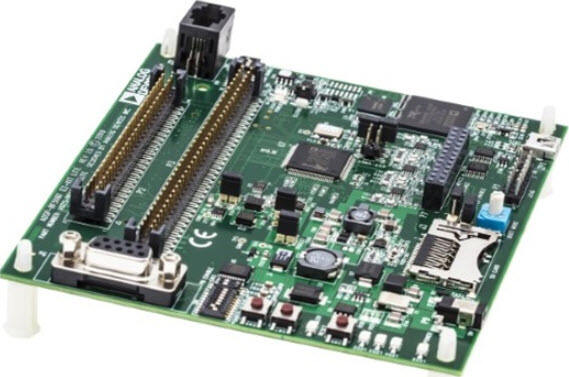

برد مدار چاپی با مس ضخیم

بردهای مدار چاپی مس سنگین دستهای تخصصی از بردهای مدار چاپی هستند که با لایههای مسی بسیار ضخیمتر، معمولاً در محدوده ۴ تا ۲۰ اونس، در مقایسه با بردهای استاندارد با ضخامت مس ۱ تا ۲ اونس مشخص میشوند. این بردها برای تحمل بار جریان بالا و نیازهای بهبود یافته مدیریت حرارتی طراحی شدهاند و بنابراین برای کاربردهای پرمخاطره ایدهآل هستند. ضخامت بیشتر مس امکان حمل جریان بهتر، پراکندگی گرما بهبود یافته و دوام بیشتر را فراهم میکند. بردهای مس سنگین از تکنیکهای پیشرفته تولید برای دستیابی به رسوبگذاری و اچ دقیق مس استفاده میکنند تا عملکرد بهینه در کاربردهای با توان بالا را تضمین کنند. این بردها شامل ملاحظات طراحی تخصصی مانند ردیفهای عریضتر و سطوح پد بزرگتر هستند تا بتوانند ضخامت بیشتر مس را در عین حفظ قابلیت اطمینان جای دهند. این بردها در کاربردهایی که نیاز به مدیریت جریان بالا دارند، مانند منابع تغذیه، کنترلکنندههای موتور، سیستمهای روشنایی ال ای دی و تجهیزات صنعتی عملکرد برجستهای دارند. ساختار محکم بردهای مس سنگین همچنین استحکام مکانیکی بیشتری و مقاومت برتر در برابر تنش حرارتی فراهم میکند و آنها را به ویژه برای محیطهای کاری سخت مناسب میسازد. توانایی این بردها در مدیریت کارآمد گرما، نیاز به مکانیسمهای خنککننده اضافی را کاهش میدهد و ممکن است طراحی کلی سیستم را سادهتر کرده و قابلیت اطمینان را بهبود بخشد.