assemblage PCBA

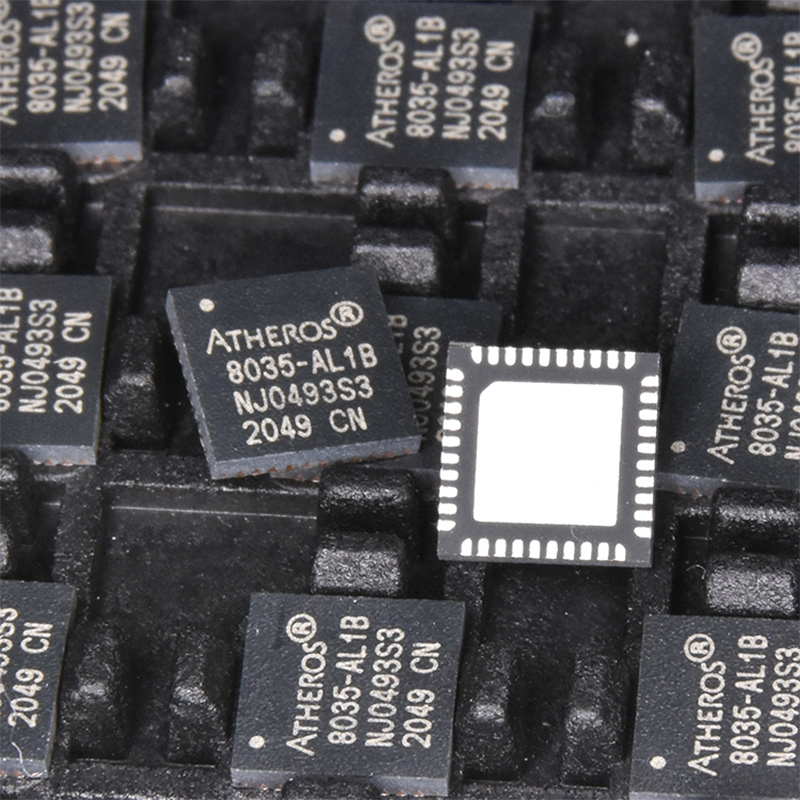

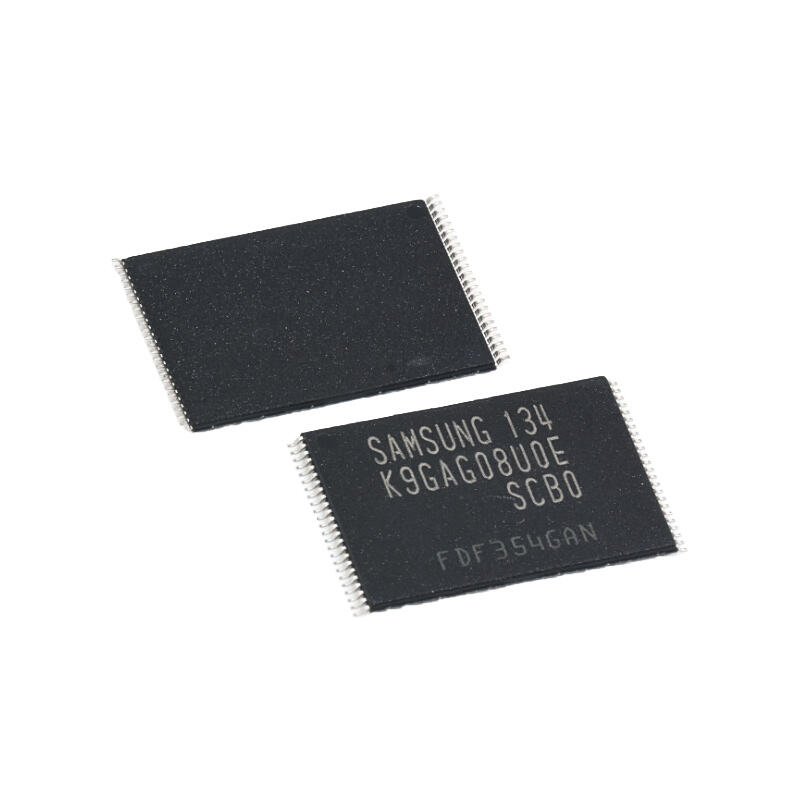

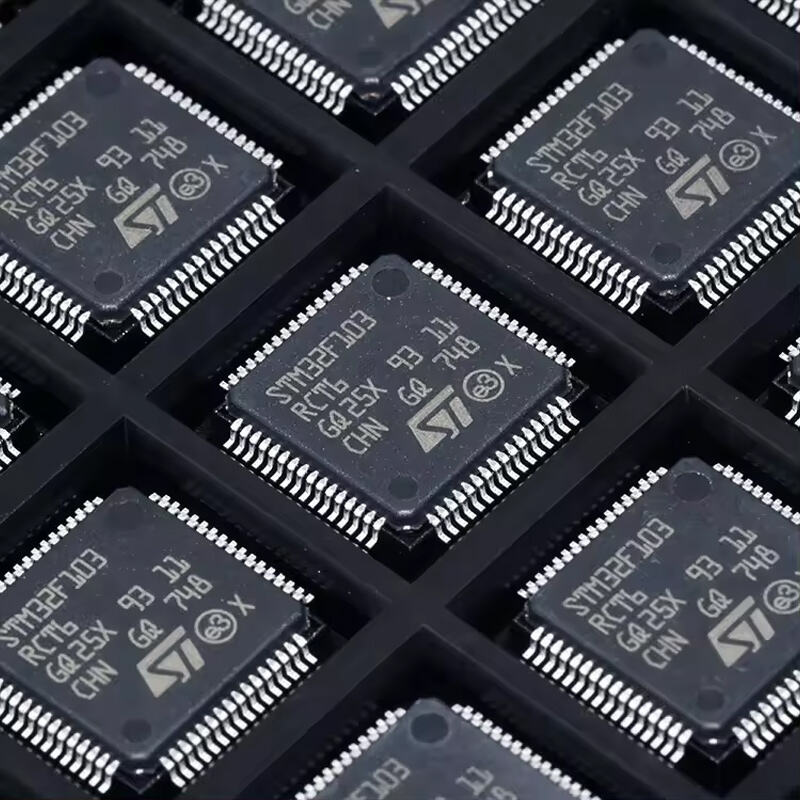

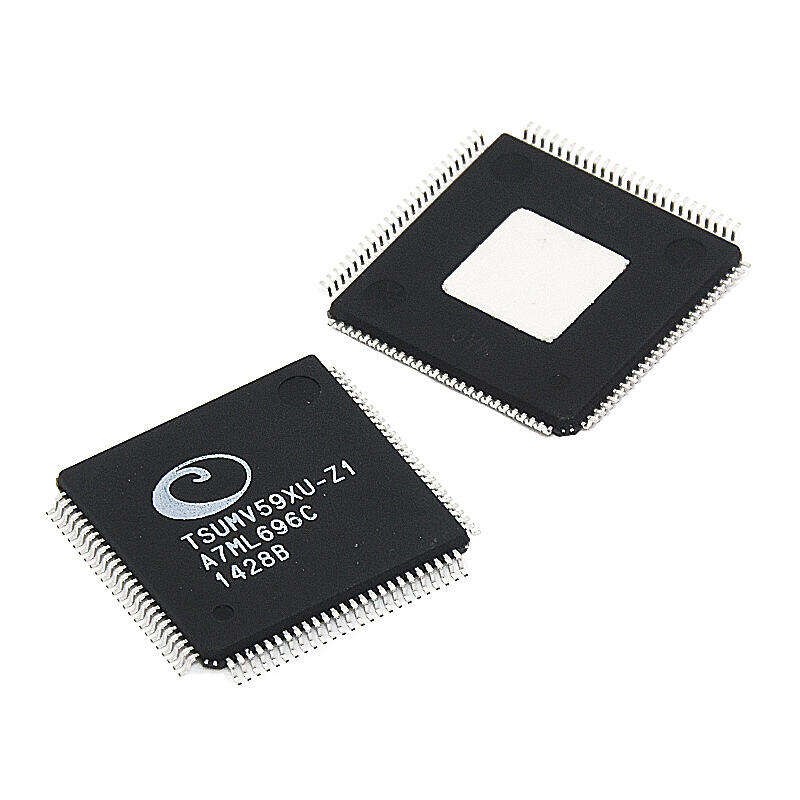

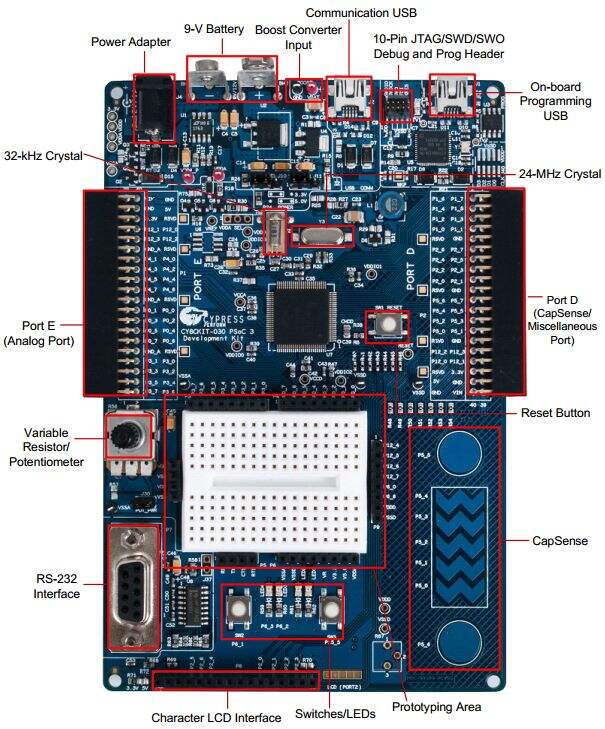

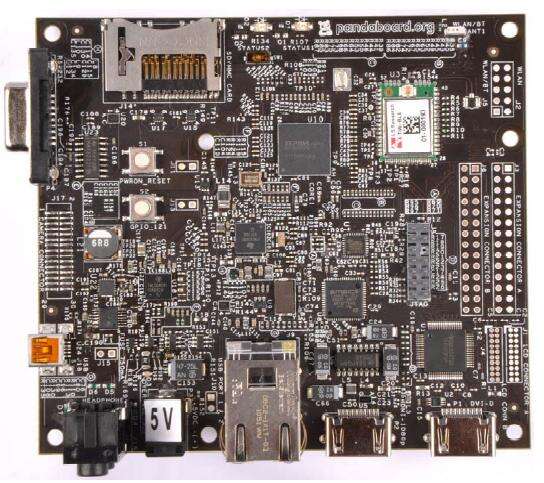

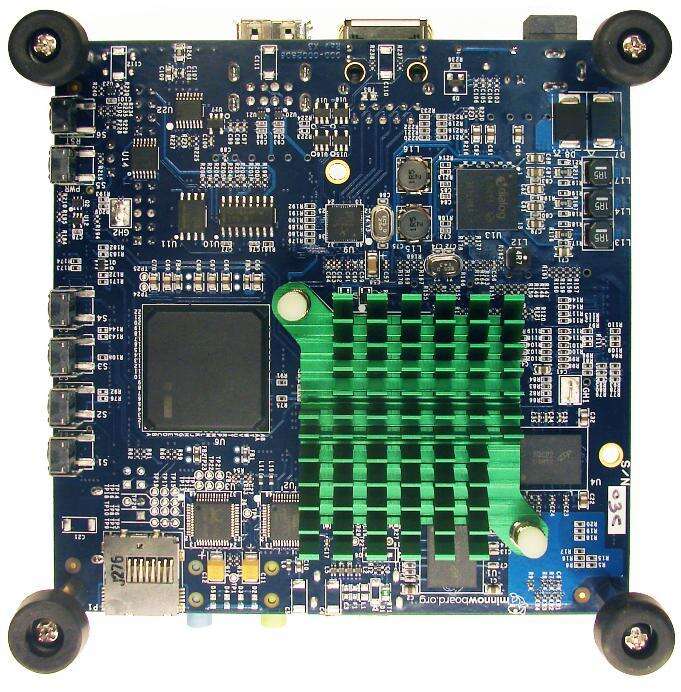

PCBA (Printed Circuit Board Assembly) représente le processus complet et le résultat de l'assemblage de composants électroniques sur des cartes de circuits imprimés. Ce processus de fabrication sophistiqué combine des technologies de pointe et des techniques d'assemblage précises pour créer des circuits électroniques fonctionnels. Le processus d'assemblage comprend plusieurs étapes, notamment le placement en technologie CMS (SMT), l'insertion en technologie trou traversant et diverses phases d'inspection afin de garantir la qualité et la fiabilité. La PCBA constitue la colonne vertébrale de l'électronique moderne, fournissant l'infrastructure essentielle pour l'interconnexion des composants et la transmission des signaux électroniques. Ces assemblages intègrent divers composants électroniques tels que des résistances, des condensateurs, des circuits intégrés et des microprocesseurs sur une seule carte, créant ainsi un système électronique compact et efficace. La polyvalence de la PCBA la rend indispensable dans de nombreuses applications, allant de l'électronique grand public aux systèmes automobiles, en passant par les dispositifs médicaux et l'équipement industriel. La fabrication moderne de PCBA utilise une automatisation avancée et des équipements de précision, assurant une qualité constante et des capacités de production à grande échelle tout en respectant strictement les normes et spécifications industrielles.