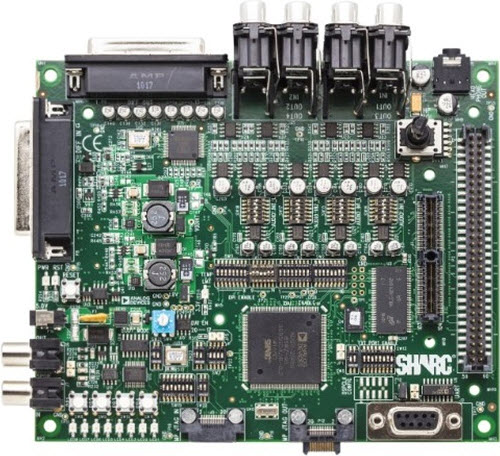

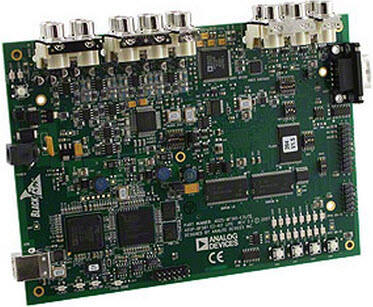

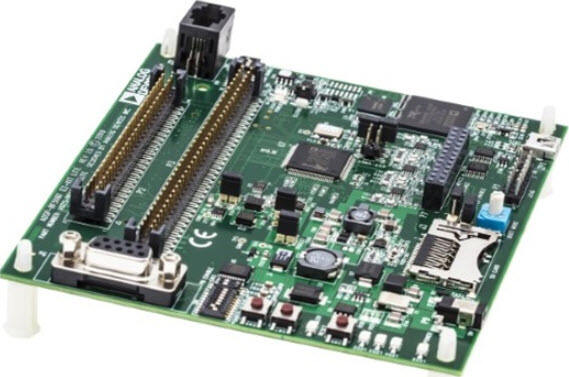

pCB de Cobre Pesado

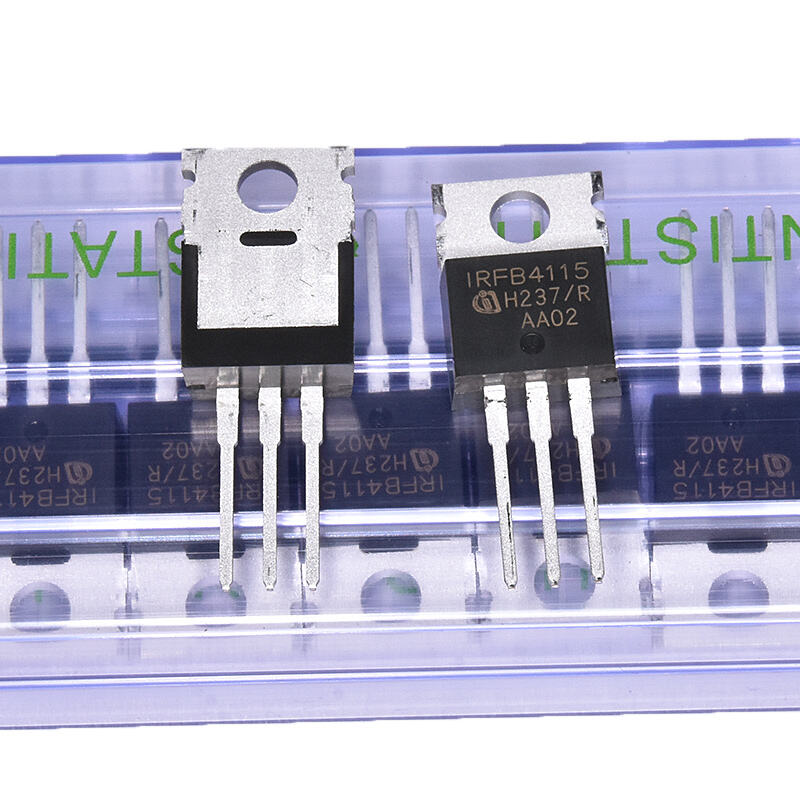

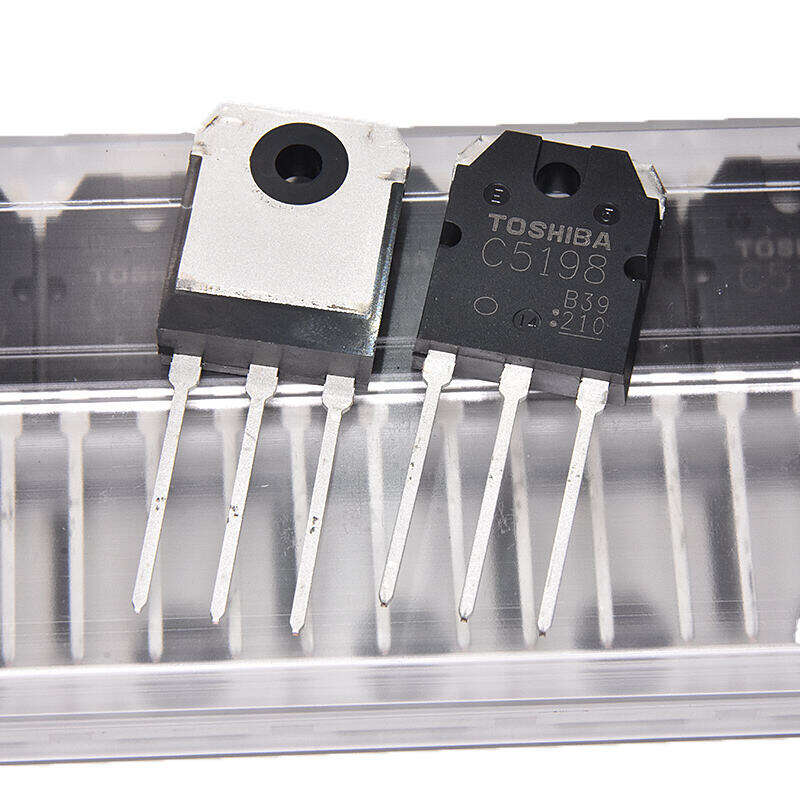

As placas de circuito impresso (PCB) de cobre pesado representam uma categoria especializada de placas caracterizadas por camadas de cobre significativamente mais espessas, geralmente variando entre 4 oz e 20 oz, em comparação com as placas padrão que possuem espessura de cobre de 1-2 oz. Essas placas são projetadas para suportar altas cargas de corrente e requisitos aprimorados de gerenciamento térmico, tornando-as ideais para aplicações exigentes. A maior espessura do cobre permite uma capacidade superior de condução de corrente, melhor dissipação de calor e maior durabilidade. As placas de cobre pesado utilizam técnicas avançadas de fabricação para alcançar deposição e gravação precisas do cobre, garantindo desempenho ideal em aplicações de alta potência. Essas placas apresentam considerações especiais de projeto, incluindo trilhas mais largas e áreas maiores nos pads, para acomodar o aumento da espessura do cobre mantendo a confiabilidade. Elas se destacam em aplicações que exigem alto manuseio de corrente, como fontes de alimentação, controladores de motores, sistemas de iluminação LED e equipamentos industriais. A construção robusta das placas de cobre pesado também oferece maior resistência mecânica e superior resistência ao estresse térmico, tornando-as particularmente adequadas para ambientes operacionais severos. Sua capacidade de gerenciar eficientemente o calor reduz a necessidade de mecanismos adicionais de refrigeração, potencialmente simplificando o projeto do sistema e melhorando a confiabilidade.