precio de placa pcb de inducción

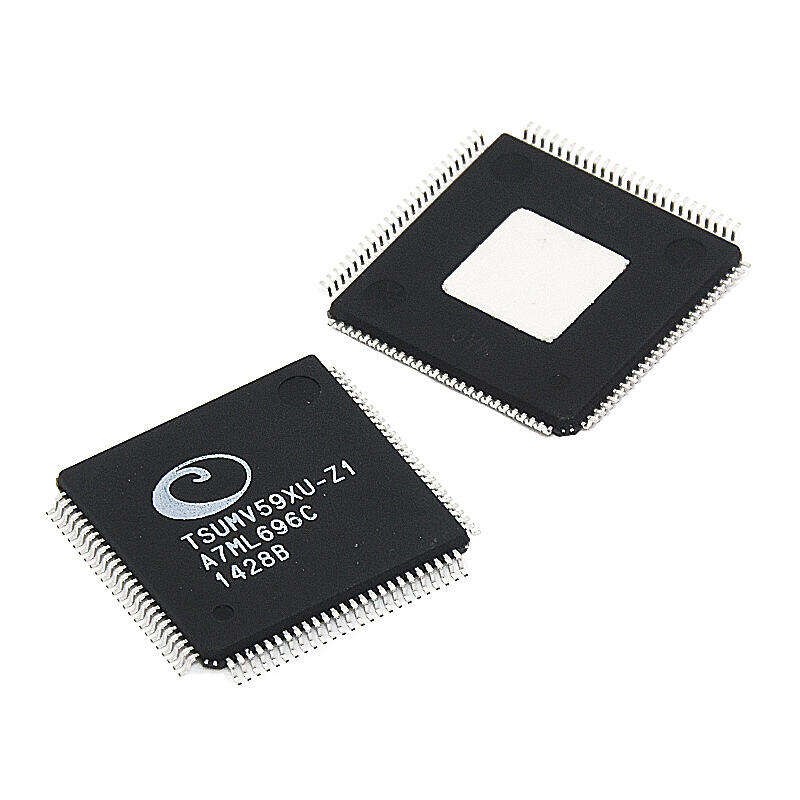

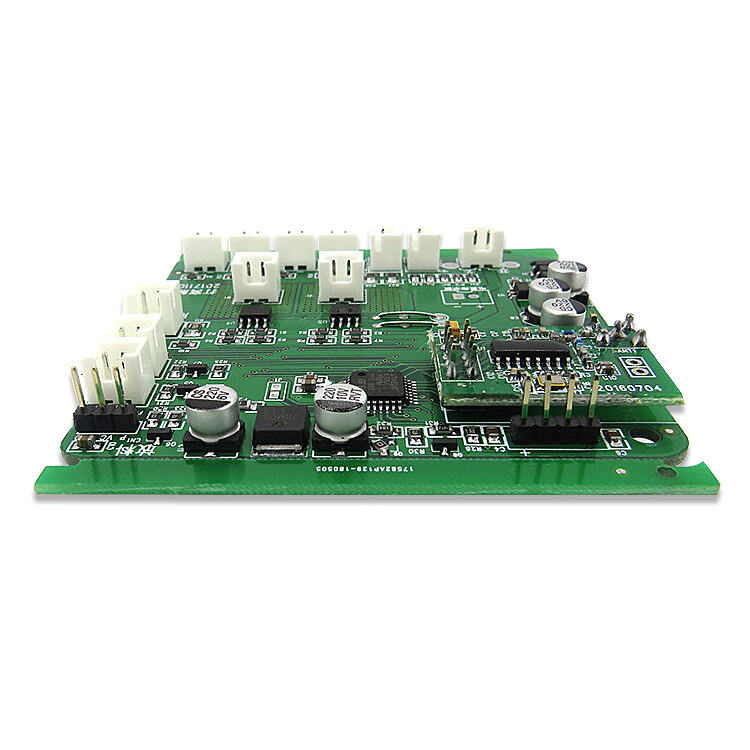

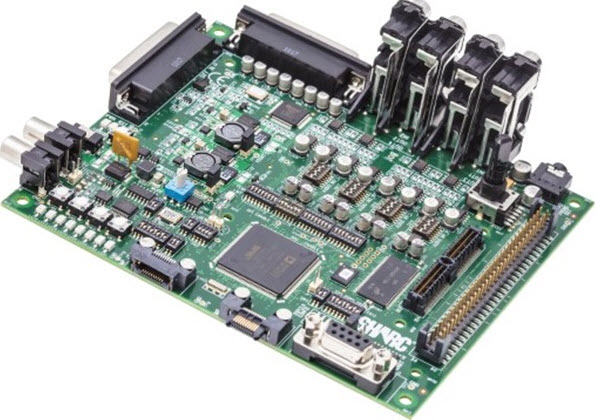

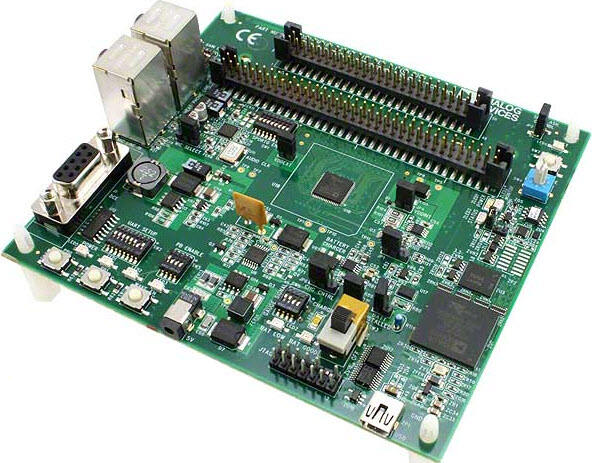

El precio de la placa PCB de inducción representa una consideración crucial en la fabricación moderna de equipos electrónicos, reflejando la tecnología sofisticada y los componentes de calidad integrados en estas placas de circuito esenciales. Estas PCB especializadas están diseñadas específicamente para aplicaciones de calentamiento por inducción, con trazas de cobre robustas y sistemas térmicos de gestión especializados. La estructura de precios varía normalmente según varios factores, incluyendo el tamaño de la placa, el número de capas, la calidad del material y el volumen de producción. Las placas PCB de inducción modernas incorporan características avanzadas como circuitos de control preciso de temperatura, sistemas de monitoreo de seguridad y redes eficientes de distribución de energía. Las placas se fabrican utilizando materiales FR4 de alta calidad o cerámicos para soportar el intenso calor generado durante el funcionamiento. Los precios generalmente oscilan entre 5 y 50 dólares por unidad, dependiendo de la complejidad y la cantidad solicitada. Estas placas tienen amplias aplicaciones en electrodomésticos, equipos industriales de calefacción y sistemas profesionales de cocina. El proceso de fabricación incluye múltiples etapas de control de calidad y pruebas, asegurando que cada placa cumpla con estrictas normas de rendimiento y seguridad. El precio también refleja la incorporación de funciones de protección contra EMI y componentes especializados diseñados para operar a alta frecuencia.